Meet the rising demand for customized and complex fabricated sheet metal products head-on. Leverage the power of shop floor data capture to minimize production disruptions and enable data-driven decision-making.

Deploy Hitech i2i, our MES software for sheet metal fabricators, designed specifically for small job shop manufacturing. Get a 360-degree view of all your production processes on a single platform. Experience higher operational efficiency with seamless dataflow across functions.

Request a demo today »

Get total control of your shop floor with real-time visibility into every stage of your manufacturing orders. Align your resources with the specific needs of your sheet metal fabrication operations. Our software perfectly meets the needs of small to medium-sized manufacturers specializing in:

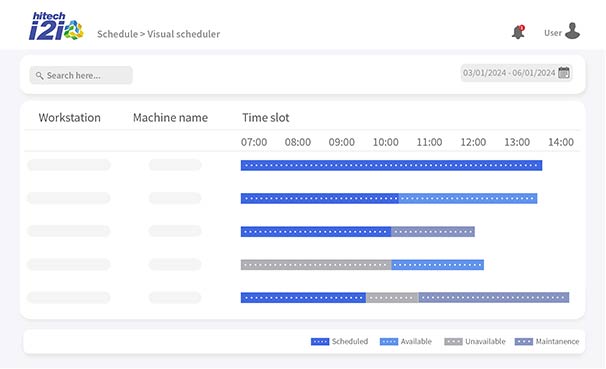

Whether you work with a variety of metal sheets or products made from the same base metal, we assist in maximizing your production throughput. Generate master schedules using backward scheduling algorithms to eliminate resource constraints and minimize last-minute hassles.

Explore more →Accurate data capturing of every movement on the shop floor, including man, material, machinery, and jobs. Regardless of the operation – whether it’s cutting, shearing, bending, or punching – use historical data to enable accurate input/output checks and consistently reduce waste.

Explore more →Eliminate the issue of metal sheets piling up or stockouts in your warehouse by using advanced demand forecasting tools. Ensure accurate material requirement planning and maintain optimal inventory levels by setting up auto-reorder points for uninterrupted production.

Explore more →Drive seamless coordination with vendors and sub-contractors through a centralized platform that manages all purchase orders. Stay industry-compliant with a single platform to manage vendor accounts, cash payments, delivery fulfillment, or anything else.

Explore more →Effortlessly plan maintenance schedules by aligning machine activities with production delivery commitments, ensuring uninterrupted fabrication. Experience seamless control like never before and elevate your sheet metal fabrication efficiencies.

Explore more →

Here are questions that sheet metal fabricators often ask us about Hitech i2i in the context of its applicability to SMBs.

Yes, MES can be customized for production process workflows, data management, user interface, compliance, scalability, automation integration, remote access, localization, and security to suit specific industry needs.

Add unlimited unique products with custom routing and production instructions; link with parent product type if relevant to minimize rework and apply similar product characteristics / specifications. However, we understand all manufacturing processes are unique so we will be undertaking an extensive requirement gathering exercises and engaging in workshops with stakeholders at all levels.

MES offers a strict quality control by offering real-time monitoring to detect issues early and keeping a detailed log. Our sheet metal fabrication software helps analyze data related to quality trends, ensuring compliance, and standardizing production processes for consistent output.

With Hitech i2i, sheet metal fabricators can access detailed reports on production efficiency, shop floor tracking, quality measures, inventory management, purchase orders and maintenance management. Our MES software has intuitive dashboards that give real-time insights into operations, and advanced analytics for trend analysis and predictive maintenance capabilities to optimize fabrication processes.

Yes, Hitech i2i seamlessly integrates with various enterprise applications and systems, such as ERP, SCM, CRM, WMS, cash flow management system, and many more. You can establish an efficient workflow with uninterrupted data exchange in sheet metal fabrication processes.

Reinvent your sheet metal fabrication operations with the future-ready Hitech i2i.

Book a demo today →