Visualize and Track Your Production Line Metrics. Effectively and Efficiently.

Map a clear route for production excellence through end-to-end process visibility and user-friendly dashboards. Define and track key production metrics like machine process, throughput, production volumes and cycle time. Identify and remedy issues in meeting strategic production objectives and set baselines and benchmarks with data sourced from across the entire production line. Close gaps in sync and visibility between remotely located operations.

Enable real-time performance visibility

Capture performance data of assets, process, streamline information distribution and drive continuous improvement with real-time insights.

Identify anomalies and risks

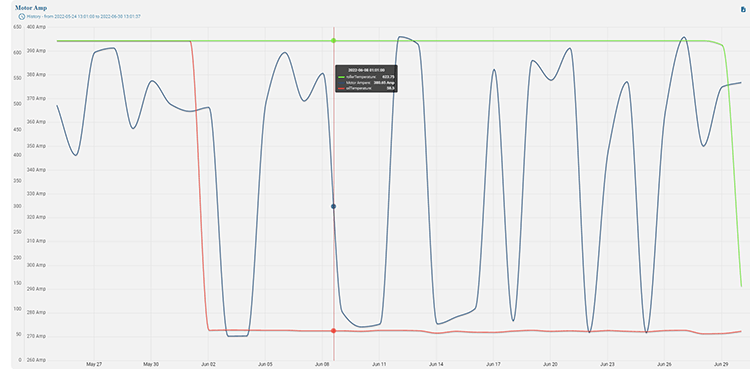

Detect deviations, abnormal patterns, and bottlenecks in real time in productions processes and take right action at the right time.

Boost resource utilization

Monitor processes across each stage for key utilization insights, such as machine health, productivity, cycle time, throughput rate, and other factors to enhance production efficiency.

Optimize performance

Visualize, analyze and improve actual process performance, quality standards, and cycle times to maintain critical process parameters and reduce wastage.

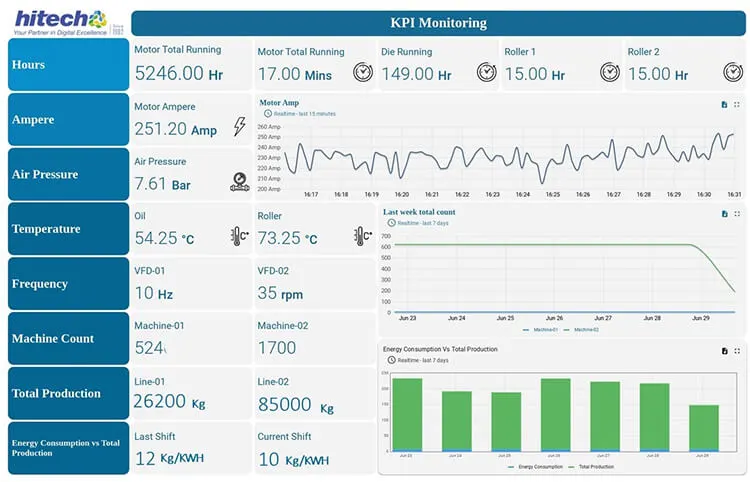

Get detailed information on the overall process parameters/KPIs of production line trends, and patterns to help supervisors make informed decisions and optimize machine operations. Leverage real-time visibility into equipment performance, efficiency, throughput rate, deviations, first pass ratio and others.

Talk to us →

Pull all complex production data into the unified interface of a customized manufacturing metrics dashboard and drive performance. Tweak dashboards with user-specific settings to monitor production and critical KPIs round the clock. Get timely alerts on anomalies and notifications for time-stamped detailed analysis and online scheduler reports.

Talk to us »

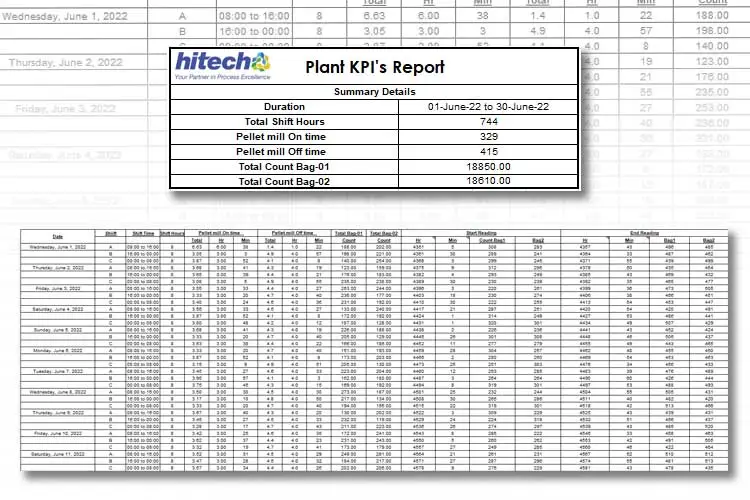

Track and analyze changes in KPIs over time. Use KPI historical data to trace irregularities in trends for root cause analysis for any chosen period through dashboards. Alter the time range, granularity of data points and perform any retroactive calculation for a higher level of prediction accuracy.

Talk to us »

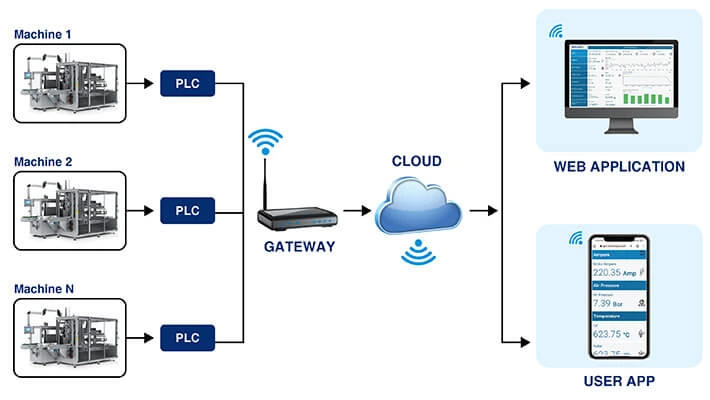

Enable easy, quick, and hassle-free integration with existing programmable logic controllers (PLCs), smart controllers, and sensors for all equipment across the shop floor. Monitor instrument and process information that flows into a live dashboard with near-to-real-time updates.

Talk to us »

Monitor your KPIs, perform continuous product data analysis, meet fluctuating needs of the production line, and do pre-emptive troubleshooting.

Consult us today →