Optimize your millwork production plans with advanced logic-driven joinery software built with the needs of woodworking companies in mind. Gain full control over subcontracted assemblies and in-shop operations. Ensure minimum schedule variance, on-time product deliveries and optimal resource utilization with Kanban view of job orders and real-time shop floor insights.

Transform your woodworking operations with Hitech i2i – a powerful millwork production software to effortlessly manage and improve shop floor operations.

Request a demo »

Never miss a delivery timeline. Ensure that your job shop runs at full-capacity with our cabinet and millwork shop management solutions. Hitech i2i empowers millworkers specializing in products such as:

Eliminate production bottlenecks with real-time visibility into machine and resource availability. Adjust order priorities with ease for manufacturing complex assemblies comprising wood, metal or hybrid materials. Quickly organize resource alternatives and listed dependencies.

Explore more →Efficiently monitor lumber, labor, equipment, and projects in real-time to control wood supplies and minimize scrap. Whether the job involves sawing, carving, joining or painting, plan dynamic routing by sequencing the operations as needed, and accurately estimate time required by each operation from past data.

Explore more →Use multi-level inventory tracking for items like wood, laminates, MDF, hinges, and locks to minimize production delays and operate lean. Optimize storage costs and stay lean by leveraging accurate demand forecasting using ML algorithms.

Explore more →Drive seamless coordination with your vendors and sub-contractors by using a centralized platform to manage all purchase orders. Stay industry compliant with a single platform to manage vendor accounts, cash payments, delivery fulfillment or anything else.

Explore more →Plan maintenance schedules for each machine across shops based on machine usage, last serviced, contract renewals etc. Continuously monitor KPI, time taken to finish identical jobs and proactively schedule maintenance to enhance machine reliability and avoid downtime.

Explore more →

Here are questions that architectural millworkers often ask us about Hitech i2i in the context of its applicability to SMBs.

For architectural custom woodworkers and cabinet makers, the key difference between MES and ERP is their focus areas. MES is designed to manage and optimize the shop floor production processes, providing real-time monitoring of jobs, machine control, and quality management specific to millwork and cabinetry production. In contrast, ERP manages broader business processes like finance, HR, procurement, and overall supply chain management.

While MES focuses on the efficiency and effectiveness of production operations, ERP provides a holistic view of the business’s administrative and strategic functions. Both systems can integrate for a comprehensive operational view.

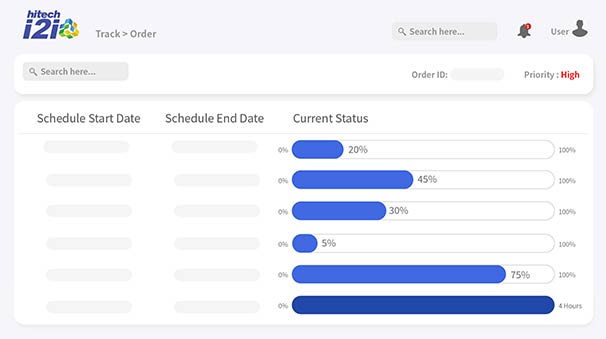

Yes, MES is a versatile millwork production software that can help in project planning and milestone tracking for woodworking shops. It provides in-built tools to set up project timelines, allocate machines, material and resources effectively, and monitor progress in real-time. It also tracks any deviations from the planned schedules and accounts for dependencies. This ensures that each project stage, from sales order generation to final dispatch and delivery, adheres to set milestones, enabling timely and efficient project completion.

Our MES software optimizes custom millwork and cabinet production by offering real-time visibility into every job order at every stage of production. It helps track and trace every movement of every part in the order to ensure no item is lost. You get greater control over quality parameters – vital for the unique demands of custom products.

Our joinery production software adeptly handles customization and variability in millwork / joinery manufacturing by offering flexible workflow configurations driven by logical-rules. It is equipped adopt to real-time changes in production scheduling due to resource constraints and efficient material and resource management. This ensures that each unique customer requirement is precisely met while maintaining optimal production efficiency.

Yes, Hitech i2i seamlessly integrates with various enterprise applications and systems, such as ERP, SCM, CRM, WMS, cash flow management system, and many more. You can establish an efficient workflow with uninterrupted data exchange in woodworking processes.

Yes, MES can be customized for production process workflows, data management, user interface, compliance, scalability, automation integration, remote access, localization, and security to suit the specific needs of woodworking shops.

Reinvent your millwork production operations with the future-ready Hitech i2i.

Book a demo today →