Eliminate bottlenecks that derail production schedules for custom architectural millworkers and furniture manufacturers.

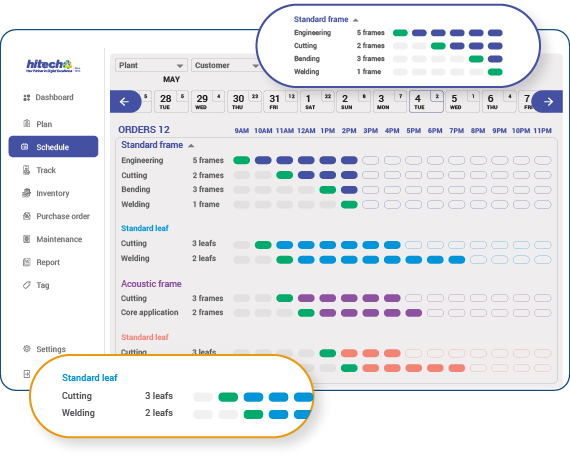

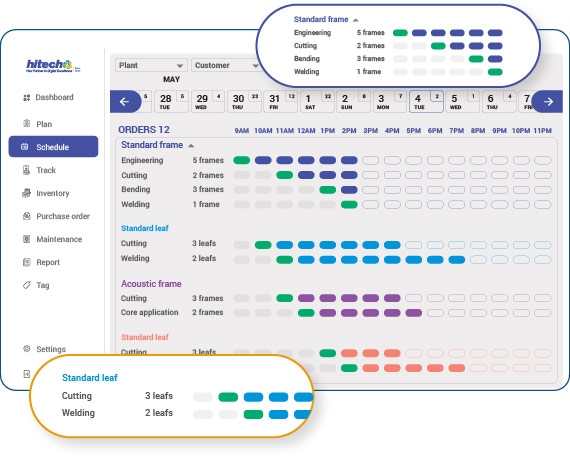

Hitech i2i, our powerful manufacturing software, gives you total control over your shop floor with intelligent scheduling algorithms. 360-degree insights about each job-machine-schedule assignment answer questions like when the cutting operation is set to start, how many jobs will be done in one set-up, or when the machine needs a reset.

Configurable modules designed specifically for your job shop integrate seamlessly with your existing enterprise applications to provide real-time visibility across the production value chain.

Embark on a winning journey. Experience the power of our exceptional service with our global presence in the US, UK, and Europe.

Millwork & Metal Fabrication Companies that HitechDigital Supports

Whether you are a contract custom furniture manufacturer, a cabinet maker, or someone creating their own architectural sheet metal products, our production planning module is for you. It will help you save resources with better order allocation, processing, and timely completion. Optimize production throughputs using real-time insights and logical workflows to beat deadlines.

Kickstart upgrading your production →Simplify complex furniture and millwork assembly processes by tracking the status of each special handling, parts, components and different materials across stages. Drive operational efficiencies and eliminate production line disruptions by detecting quality fluctuations early with real-time visibility and effective backtracking.

Turn on the lens for 360 degree shop floor view →

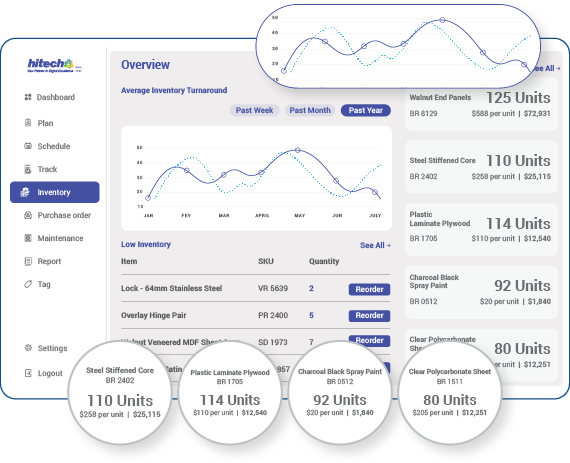

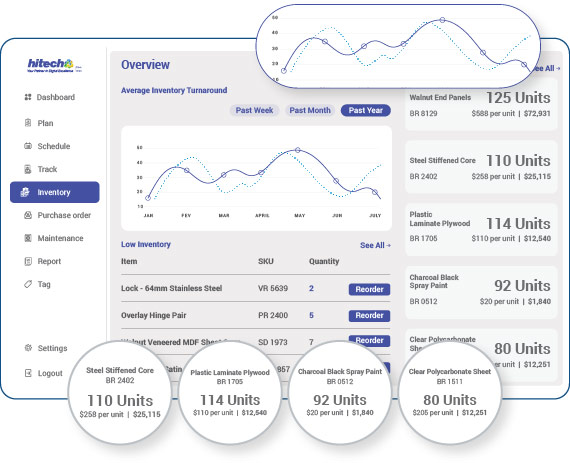

Track and trace inventory for various sizes, styles, and finishes in real-time. Achieve a perfect balance between stocked components and allocated inventory to stay lean even with high customization. Forecast demands and lead times for suppliers for specialized, slow-moving inventory to avoid excess carrying costs.

Start tuning your inventory for lean operations →

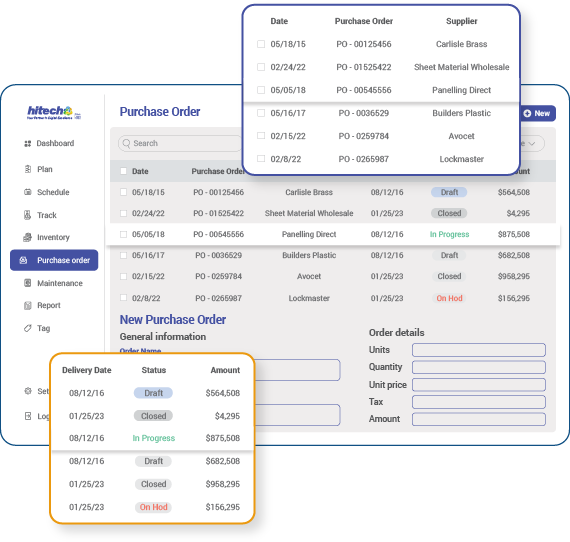

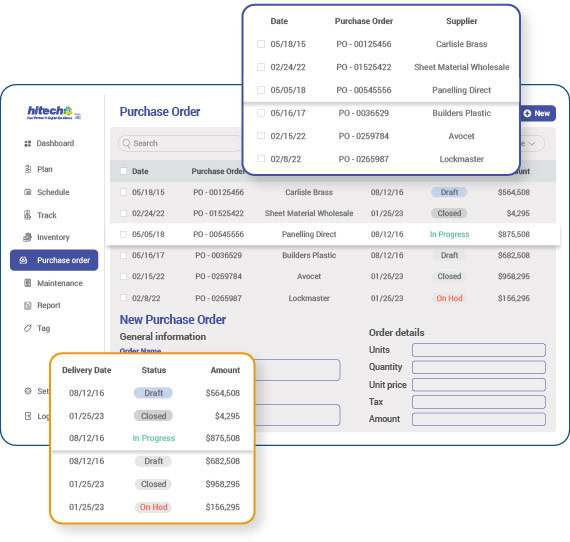

Streamline purchase order processing for both unique and standard raw materials and components, with an integrated view of PO lifecycle drill-down reports, and cross-functional reconciliations. With centrally accessible POs, drive consistency in procurement processes for unique terms, conditions and delivery schedules across suppliers.

Gain total control of PO lifecycles →

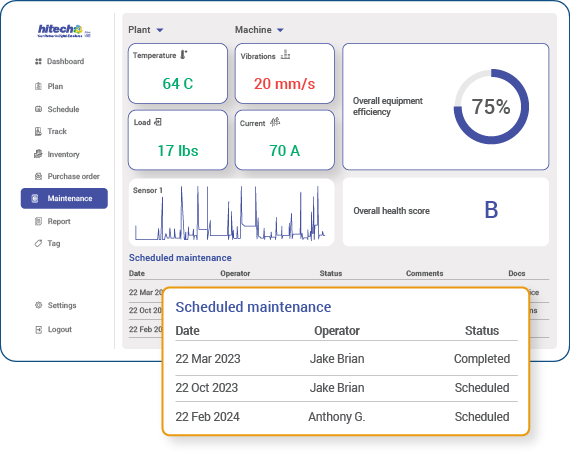

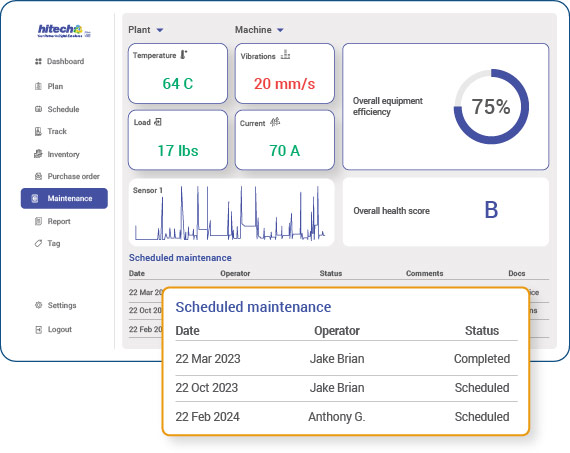

Plan maintenance schedules for machine cleaning, blade replacement and sharpening, lubrication, etc. for enhanced machine reliability and availability. Optimize overall machine health through real-time tracking and analysis of machine metrics. Avoid unplanned machine downtime to eliminate production bottlenecks.

Checkmate machine downtime and maintenance issues →

Cloud-based MES solutions for metal fabricators and architectural millworkers

Find out why fabricators and millwork companies love HitechDigital. Start streamlining operations.

Download Brochure →Cutting-edge MES features to scale up operations and further your manufacturing goals

Leverage Industrial Internet of Things (IIoT) to build a smart, connected manufacturing ecosystem by deploying sensors and transform your workshop/factory. Use real-time data insights to streamline operations, quality, maintenance, processes, inventory and energy use.

Make faster responses to market changes and growing production needs as our manufacturing software scales and adapts to your technical infrastructure upgrades, additions and changes. Scale operations up or down with no disruptions on the shop floor or to brand experience.

Enjoy the advantages of quick issue resolutions, a robust IT infrastructure, and an experienced helpdesk focused on fostering collaboration. Get quick and responsive support from technical teams working round the clock to ensure your manufacturing software operations are always up and running.

Implement paperless planning and manage all your data with a unified view on secure cloud infrastructure to increase communication and collaboration. Protect all your data and access it from any device for sharing and teamwork.

Integrate datasets across enterprise applications and eliminate manual data updates. Get a holistic view of operations in your job shop and gain contextual insights.

Our technical and functional analysts make MES deployment a smooth and seamless experience. We identify your customization and integration needs, and where the MES can make the highest impact in meeting production goals and get you operational within 90 days.

What architectural millwork manufacturers and metal fabricators need to know more about our MES solutions

A Manufacturing Execution System is a system that drives visibility across stages from purchase order release to production and dispatch. It ensures effective execution of the manufacturing operations, gives a holistic view of the shop floor in real-time, prioritizes inventory allocation and optimizes overall production capacity.

IIoT stands for Industrial Internet of Things. It refers to the network of interconnected devices, sensors, machines, and systems in the industrial environment, enabling data collection, communication, and automation. IIoT offers real-time data collection and visibility for enhanced operations of MES. It helps tracking raw materials and inventory, start and end of operations to improve operational efficiency, ensure quality control and enhance decision making.

Start by considering your business goals. Are you looking to digitalize paper-based records, drive data-backed decisions, gain visibility across your operations? If your business goals resonate with these achievements, then an MES is the right choice for you. You will then need to assess compatibility across enterprise application, implementation costs and change readiness.

If you’re unsure of how MES can help you or if you have got the right infrastructure, get in touch today and we can do a detailed assessment to evaluate how MES could be useful .

The complexity of implementation varies depending on the specific MES and the existing systems you have in place. However, with a well-defined implementation plan, the right team, and support from the MES vendor, it can be implemented successfully.

No, an MES rather complements ERP systems. While ERP systems focus on planning and managing resources across the business, MES systems focus on the real-time monitoring and control of shop floor activities. By integrating both, you get a holistic view to drive informed decisions. Alternatively, an MES can work independently without an ERP system in place – let us know how you maintain your data and we can suggest the best way to get started.

HitechDigital offers initial training and ongoing maintenance for seamless implementation and operations. This includes on-site training, user manuals, and ongoing support for upgradations.

We approach MES implementation in a phased manner. After an initial assessment, we assist you in identifying the modules that are critical for your business and prioritize their implementation. Following that, the implementation can be completed within 90 days. And you can start realizing the benefits almost immediately. Share your needs with us to get started with the implementation process.

The decision to implement Excel, Project Management tools, or Manufacturing Execution Systems (MES) depends on the specific needs and requirements of your business. All three have their advantages and limitations. But if you are looking to optimize manufacturing operations, improve productivity, and gain real-time insights into shop floor activities, you need an MES. Excel and Project Management tools are capable of managing data, analyzing it and managing projects digitally.