Predict and pre-empt system malfunctions and failures with intelligent machine health monitoring

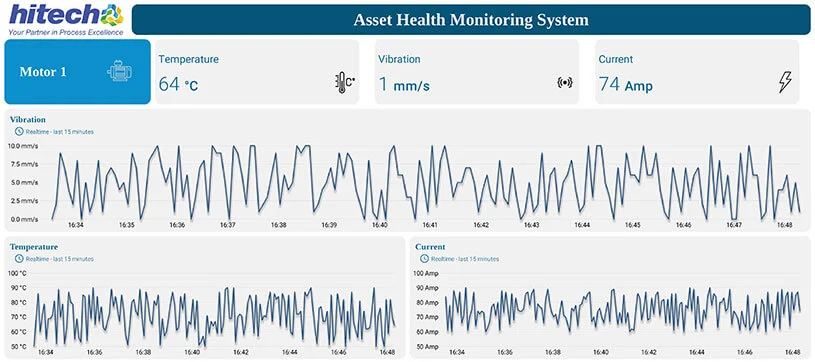

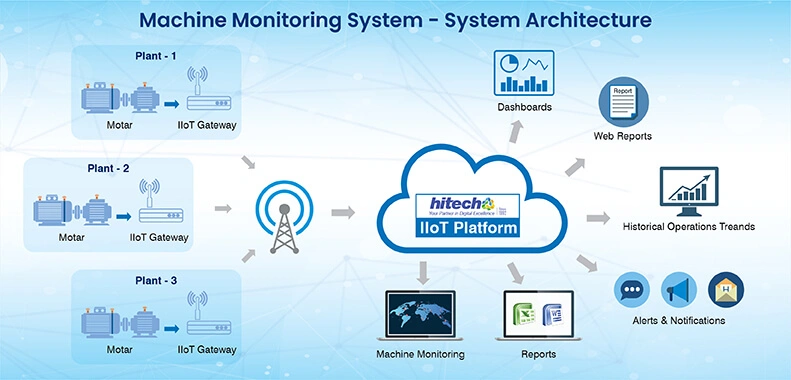

Monitor plant equipment conditions like temperature, vibration, pressure, and other metrics and detect anomalies in real-time with condition-based monitoring. Use IoT-enabled sensors and AI for greater visibility of shop floor assets through an interactive dashboard. Get timely alerts on trouble spots and prevent operation breakdowns.

Increase machine lifespan

Collect and analyze machine health data to manage equipment life, utilization, and performance

Prevent production losses

Get real-time alerts and notifications on anomalous behavior and to prevent machine failures and losses.

Optimize plant uptime

Generate insights to enable timely maintenance and first-call resolution to ensure higher machine uptime.

Minimize workforce safety risks

Create an environment to facilitate healthy human interactions with machines at work sites and maintain safety standards.

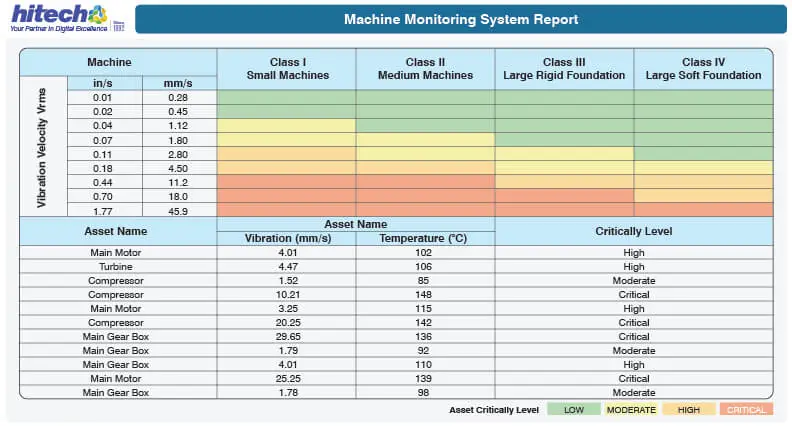

Prevent unplanned machine breakdown by continuously monitoring biaxial vibration, acoustics, temperature etc. to sustain equipment health.

Request a Demo →

Host all your data securely on a cloud server. Seamlessly access your data through IIoT-enabled platform from any location and on any device.

Request a Demo →

Identify anomalies in patterns and trends. Get notifications in real-time through an integrated dashboard and conduct detailed analysis.

Request a Demo →

Draw actionable insights in real time for predictive and preventive maintenance of plant equipment, extend the life and utility of assets with data-driven decisions.

Schedule a Demo →