Get a live, integrated view into furniture production processes along with resource constraints for logic-driven scheduling. Capture real-time data at the workstation and machine levels across your shop floor, meticulously monitoring the progression of every order.

Streamline shop floor operations with Hitech i2i - a leading furniture manufacturing software offering centralized platform to collaborate across functions. By consolidating production data, Hitech i2i drives proactive planning and enhanced control.

Request a demo »

Effortlessly manage custom furniture production with Hitech i2i. Gain detailed schedules for all assets on the shop floor and smartly coordinate production plans across various furniture types like:

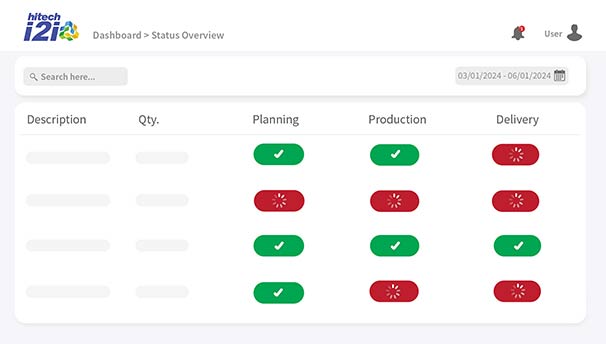

Prioritize planned orders based on attributes like customer priority, delivery dates, and material availability to generate an automated production schedules. Keep buffer and dynamically adjust schedules using logical rules and real-time capacity analysis.

Explore more →Enhance your shop floor with data connectivity and integration to efficiently manage orders, machines, workstations, and manpower. Maintain a quality log and identify issues by raising alerts in real-time. Watch your live track metrics by type of product and material based on real-time data collection of shop floor operations.

Explore more →Maintain optimal stock levels by tracking everything from rare individual components to fast-moving inventories as orders progress towards finished product. Implement a robust inventory management system to quickly identify, locate and replace defective materials, for uninterrupted production.

Explore more →Experience hassle-free PO management through virtual collaboration with suppliers, boosting profitability and compliance with industry standards. Get centralized coordination, vendor account management, cash payments, and delivery fulfillment with a PO management system tailored for the needs of the furniture manufacturing industry.

Explore more →Embrace proactive maintenance solutions, designed to ensure reliable CNC machine operations such as cutting, drilling, and punching. Minimize machine downtime and keep your custom furniture manufacturing running smoothly with predictive maintenance strategy driven by advanced ML algorithms.

Explore more →

Here are questions that furniture manufacturers often ask us about Hitech i2i in the context of its applicability to SMBs.

MES (Manufacturing Execution System) focuses on the shop floor, tracking and documenting the transformation of raw materials to finished goods. It’s vital for real-time monitoring and control.

ERP (Enterprise Resource Planning) integrates various business processes (like accounting, HR, and supply chain) into a single system, providing an overarching view of the entire business, including manufacturing aspects.

MRP (Material Requirements Planning) is primarily concerned with materials planning and inventory control. It ensures materials are available for production and products are available for delivery to customers.

Our MES offers real-time data collection and analysis, enabling manufacturers to optimize production schedules by predicting delays, balancing workloads, and reducing downtime. This furniture production software dynamically adjusts schedules based on various factors like machine availability, labor, and material constraints.

Yes, our furniture manufacturing software integrates with a variety of shop floor machines and tools. It enables automated data collection and control, providing a seamless flow of information between machines and MES for enhanced efficiency and accuracy. It gives you insights into pending requirement and feasibility assessment.

MES assists in quality control by tracking production processes in real-time, identifying deviations from quality standards, and providing alerts. This allows for immediate corrective actions, reducing waste and ensuring consistent product quality.

Our furniture production software provides a range of reports, dashboards, and analytical tools that offer insights into production efficiency, process compliance, quality control, and more. These tools can be customized to meet specific requirements, providing key performance indicators and real-time data for informed decision-making.

With Hitech i2i, implementation typically takes about 90 days, after which noticeable results can be observed. This MES software is specifically designed for the furniture manufacturers, featuring a user-friendly and intuitive interface. It is scalable and customizable to meet diverse customer needs. According to our clients, Hitech i2i performs optimally in shops with 10-25 employees. It offers small enterprises the advantage of a sophisticated system without the complexity or costs associated with larger systems.

Reinvent your furniture production operations with the future-ready Hitech i2i.

Schedule a demo today →