Client Profile.

The client is an Asian company that manufactures wooden pellets from saw dust to be used as fuel in burners, boilers and thermic fluid heaters in the food industry. They deploy heavy-duty machines for grinding, pellet making and cooling processes to meet a daily production capacity of 30 tons.

Business Need.

The wooden pellets manufacturer used analog meters and paper-based systems to track and maintain energy parameters across the plant. The data sources used for the purpose were resting in silos. As a result, there was limited visibility into cross functional areas, as well as high chances of errors and manipulation in daily records.

Fluctuating phase voltage also led to hazardous fire incidents in the plant’s main feeder, impacting workforce safety, production output and equipment performance.

The manufacturing company hence partnered with Hitech to deploy an intelligent Energy Monitoring System to:

- Track all relevant energy parameters in real time across the plant

- Seamlessly adhere to energy parameters’ standards range

- Reduce manual dependency to maintain accuracy in reports

Challenges.

- High dependency on analog meters impacted access to historical energy patterns.

- Disparate sources of data from multiple energy meters didn’t give an integrated view of energy trends.

- Ineffective and inaccurate data collection methods derailed efforts to track actual energy consumption.

Solution.

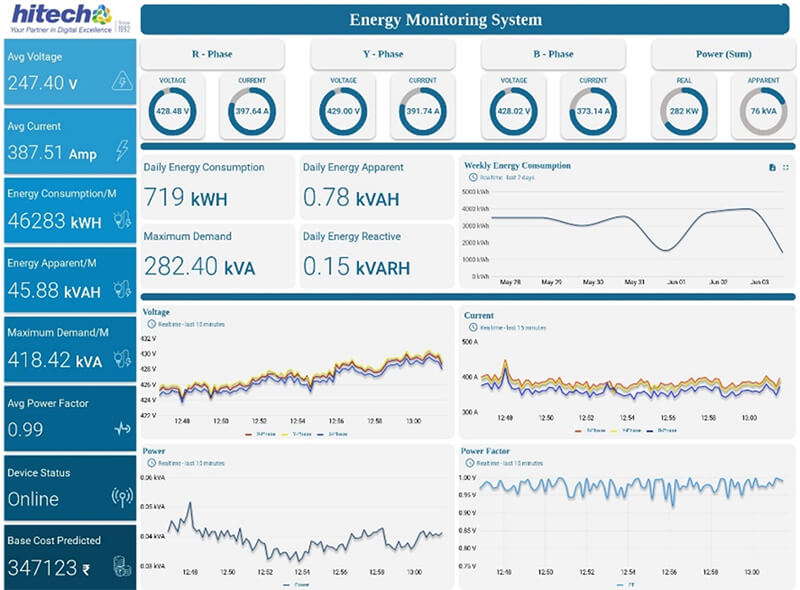

Deployed the smart Hitech Energy Monitoring System for integrating varied and disparate data points across the plant related to various energy parameters. The solution provided:

- 100% visibility into energy related parameters across the plant

- Automated SMS, email and web-based alerts and notifications on breach of pre-defined threshold parameter values

- Easy-to-understand and automated daily/ monthly energy status reports through emails

Approach.

Assessment and Documentation of As-is Conditions:

Based on a detailed onsite assessment, the Hitech team identified challenges and scope of work.

- They highlighted that the energy meters were outdated and functioned in siloes without a single communication (OT) network.

- Defined a list of critical parameters including kWH, kVAH, kVARH, PF, Maximum Demand, Voltage, Current, etc.

- Identified power consumption patterns across the plant from the last few monthly electricity bills.

- Set up a standardized format for daily status reports along with a quick summary to be shared over email to all stakeholders.

Deployment of Custom EMS:

- Installed new energy meters in the main plant feeder, and Current Transformer (CT) on bus bar. Connected energy meter with IIoT gateway in the main control room to collect accurate data.

- Connected all devices in a single daisy chain OT network to avoid multiple data connections, monitor critical energy parameters in real-time.

- Set energy benchmarks with upper and lower limits to enhance energy accounting, operational and maintenance activities for incomer, capacitor bank and plant feeders.

- Delivered a web-based intuitive dashboard for real-time visibility of exact status of multiple energy parameters. Send daily accurate reports for required energy parameters through email to all relevant stakeholders.

- Shoot out instant alerts and notifications through web app, SMS and emails to respective users for any breach of threshold limit for different energy parameters.

- The EMS focused on:

- Analyzing and interpreting energy meter data to estimate monthly bills, energy consumption etc.

- Giving end-to-end process visibility across energy parameters.

- Delivering data-enriched insights to the client to evaluate all energy related activities.

Tools and Technology Used:

- IIoT platform, IIoT gateway, AWS and PostgreSQL