Client Profile.

Manufacturer of RV Vans and accessories, Australia

Industry: Automotive Industry

Objective.

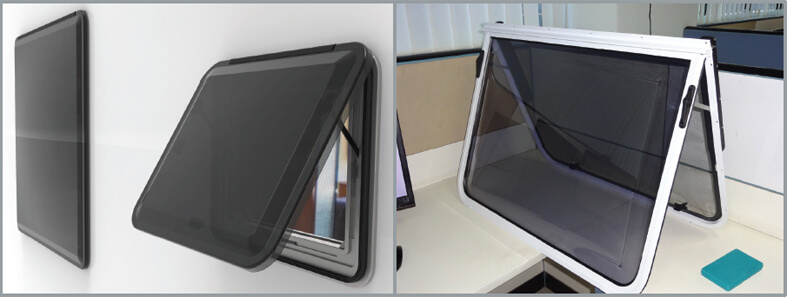

The client, a manufacturer of RV vans and premium supplier of parts and accessories, wanted to redesign and patent them for manufacturing rights of several bought out parts of doors and windows and manufacture them at his own capacity by developing virtual prototypes. HitechDigital project team delivered 500+ variants with all the engineering details necessary for manufacturing.

Business Needs.

- Upgradation of existing designs for doors, windows for RV Van.

- To reduce the product cost, remanufacture doors and windows with value additions, redesign and patent which are already purchased from the vendor.

- Reverse engineer and develop CAD models for replicating parts purchased.

Challenges.

- Complex parts of doors and windows makes it difficult to measure and record the geometry.

- Quality and accuracy in modeling the existing designs to meet end client requirements is always a hurdle.

- Adding value to designs for avoiding copy rights infringement of patented products existing in markets.

- Meeting deadlines for delivering models and drawings with QC of complex parts within shorter time.

HitechDigital’s Solution.

- HitechDigital engineers received the information for reverse engineering and recorded information to record the geometry and dimensioning of doors and windows.

- Detailed drawings and CAD models were developed using SolidWorks latest software versions with PLM support.

- BOMs, metadata sheets, inventory list for windows, along with other design related manufacturing information for more than 500 variants were delivered by project team, within specified timeline.

Approach.

- HitechDigital engineering teams received the hand sketches, physical equipment for recoding geometrical information and STEP files for review to develop CAD models to redesign and develop virtual prototypes for validation.

- A step by step disassembly of the component were done and geometry was recorded by either scanning or manual measurement to understand company standards and templates of drawings.

- Each part was recorded and 3D CAD part and assembly model were developed using SolidWorks.

- Several options were given to the client review and approval before finalizing the 3D design and patent registration.

- BOMs, metadata sheets, 2D drawings for manufacturing along with animation video were delivered to the client.

Benefit.

- Created digital record of the door and windows of RV Van for future referencing.

- Safe, secure and flexible data allowed manufacturer to implement design changes easily.

- Quick turnaround time for initiating manufacturing and delivery.

- Reduced the cost of maintaining inventory.

Results.

- Design value additions for each type and sizes.

- Establish own manufacturing capacity for doors and windows.

- Registered patents for different variants.

Client Speaks.

HitechDigital engineers showed eagerness and remained proactive to help us reverse engineer the designs and they willingly went extra lengths to deliver value engineering factor to our designs and take us a step ahead.