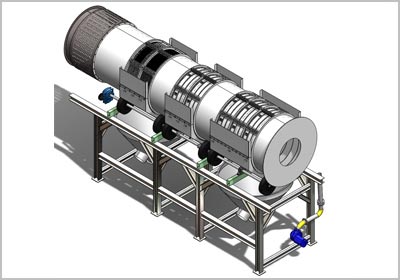

Recycling Plant, Europe

Reverse engineering plays important role in re-establishing or re-inventing the part, process or the entire system that were possibly developed during pre-computer era. A recycling plant in Europe, established multiple decades ago, needed to reverse engineer their plant in order to document the information that was previously unavailable.

To reverse engineer complete recycling plant and document the information to manipulate further.

The plant was successfully developed virtually with a team of CAD professionals and industry leading CAD tools. The entire plant data including equipments, assemblies and sub-assemblies were accurately documented with 3D drawings, detailed manufacturing drawings and process information.

The project was successfully executed by a team of engineers at HitechDigital, who visited the plant physically to calculate dimensions, performed design calculations on-site and gathered manufacturing process data to serve as an input to the reverse engineering process.

In order to appropriately document the dimensional and design information, professional CAD tools were utilized to create general arrangement drawings, 2D and 3D layout of the plant as well as detailed manufacturing drawings. The details gathered on-site were restructured to replicate the original arrangement accurately, considering the tolerances, surface treatment processes and material requirements.