Power plant equipment manufacturer, Mexico

Industry: Energy and Utilities

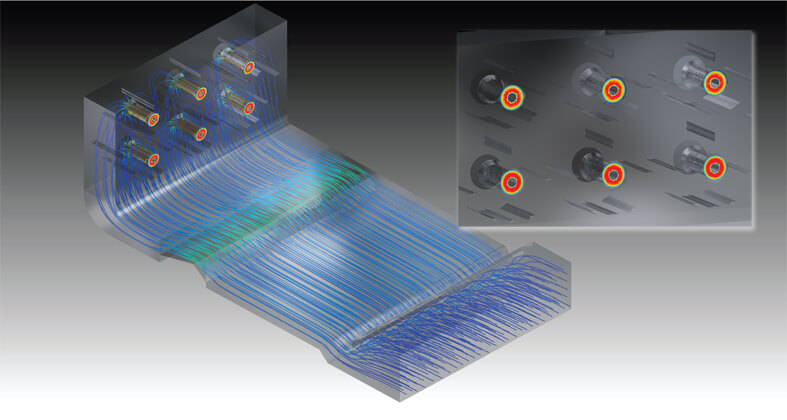

It was observed that the air flow at the burner showed irregular pattern of secondary air flow at the burner exits from the wind box resulting in decrease of boiler efficiency. Client, the manufacture of power plant equipment approached HitechDigital CFD analysts to simulate the air flow to have insights for design optimization by uniform air flow at the burner exits.

Wind box and burner arrangement were modeled through CAD tools and flow at the burner exit was simulated using ANSYS Fluent 14 to measure the uniformity of air flow. The results showed non-uniform behavior of secondary air flow and increased emission rates. As an alternative for achieving optimized design, baffles at different locations were suggested. The simulation results of modified designs showed uniformity in flow with a variation of ± 2%.