An American company into the design and manufacturing of pressure vessels for the oil and gas sectors worldwide.

The company was looking to partner with CAE experts for Pressure Vessel FEA Analysis and Life Estimation Consulting as per ASME Section VIII, Div-2, Part 5 (DBA).

Identifying all the factors (as per ASME) and the critical locations in the vessel where peak stresses are expected.

Preparing structured hexahedral mesh of complete pressure vessel without losing critical areas of peak stresses like nozzle fillets, etc.

Fatigue calculations for allowable stresses of different components (Shell, Nozzle, Dish End) and comparing against the predicted cycle life of the vessel.

Completing all analysis and calculations within quick turnarounds.

HitechDigital’s CAE team provided solutions well ahead of the deadline. This included

FEA Analysis and Life Assessment

Process Optimization

Re-evaluating and enhancing operating parameters for engineering analysis.

Technology

Modeling and Analysis: SOLIDWORKS®, ANSYS WORKBENCH®®

Automation: ANSYS APDL, plugins, custom developed in-house programs

Standards / Compliance

ASME

Modeling and Simulations

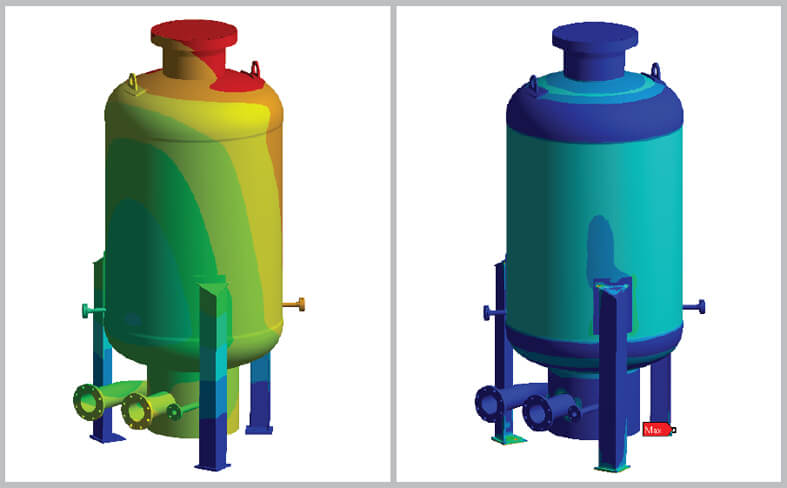

Performed analysis of the model for fatigue stress through FEA techniques using ANSYS. After finding maximum stress, stress range, maximum deformation points, etc.

Meshing

The geometry was meshed with hexahedral elements using ANSYS WORKBENCH, following the quality criteria provided by the client.

Structural Assessment

Structural assessment using ANSYS and Fatigue life calculations according to ASME Section VIII, Division 2, Part 5.

Accelerating through Automation

Used ANSYS APDL, plugins and developed in-house programs (as per ASME) to speed up work processes.