A U.S.-based company manufacturing and supplying custom metal and steel doors and frames for over 25 years.

The company was looking to significantly cut down on engineering time and speed up the delivery of their products. Achieving abilities to assure deliveries within 24 hours for more than 50% of their orders was the plan to get a huge competitive advantage.

Legacy systems and traditional detailed engineering work processes that made custom product deliveries a week-long process, as measurements and customer specifications varied across orders.

New technology investments and continuous training and hiring was going to escalate operations and productions costs, dig into profits, and pose risks of losing competitive advantages and market share.

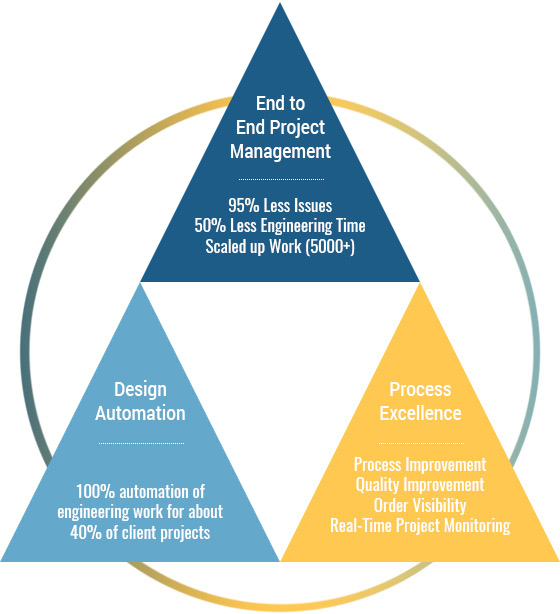

HitechDigital partnered with the client to take on their end-to-end design development processes, and enabled process excellence initiatives to reduce overall engineering time by 80% and achieve 99.7% quality levels. This was achieved in three phases.

End-to-end engineering project management

Through an engineering team, with certifications in metal and steel door designs of different profiles, and expertise in SOLIDWORKS® and DriveWorks®, HitechDigital offered the following solutions.

Design Automation

An authorized partner for DriveWorks implementation, HitechDigital automated design processes, reducing client’s engineering time by over 60%. This second phase involved:

Process Excellence and Continuous Improvement Initiatives

Rising monthly order volume called for systems in place to track orders at individual customer levels. And increased overall quality control time. In response to this, HitechDigital offered several solutions: