The client is a UK-based custom furniture manufacturer specializing in stainless steel furniture for commercial kitchens.

The furniture manufacturer’s business of commercial steel furniture hinged on sales inquiries on their website. The sales process involved picking up the enquiry, understanding design intent, communicating design and specs to the engineering team, estimation of material and other costs by engineering team and then having the sales team respond to customers with a quote. The process was many a time iterative with dilution of design intent or shifting customer design preferences which called for a need to rework quotes.

The client approached HitechDigital to help accelerate the engineering lead time by embedding interactive and configurable 3D design models on the website. This would help customers communicate design requirements accurately and the sales team quote quickly.

Every inquiry that the client received was unique. Hence, the biggest challenge for the project team was to put together a database that could handle large datasets while being cost effective. Other process challenges included:

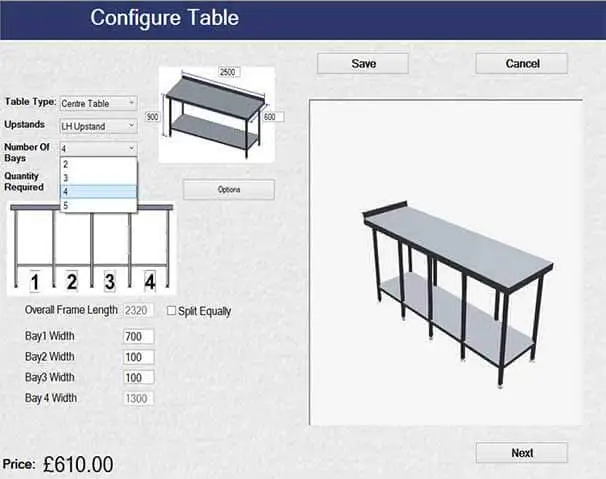

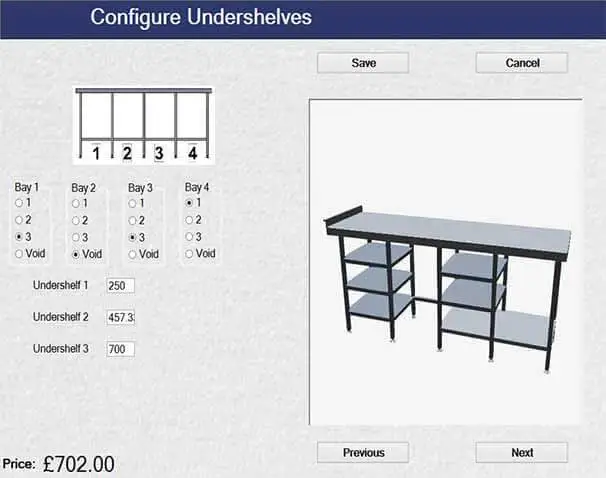

A table configurator was developed using DriveWorks Pro Administrator and SolidWorks and deployed on the client website. The configurator allowed customers to self-configure their designs and get a 3-dimensional view of the customized model on screen. It also offered instant sales quotations based on model specifications. The secure login credentials offered design confidentiality.

Configure Table

Configure Table

Configure Undershelves

Configure Undershelves

An initial assessment of as-is process suggested that the client spent most lead time in quote calculation and use of 2D AutoCAD workflows contributed to delays. So, to accelerate engineering lead time, the project team suggested implementing 3D workflows with SolidWorks and automation with DriveWorks configurator.

Technology