Client Profile.

Manufacturer of shop fitting products, Europe

Industry: Retail Furniture

Objective.

The client, a manufacturer of retail shop fitting products, had ready manufacturing drawings for made-to-measure products, which were not informative enough for installation engineers on site. HitechDigital engineers developed installation guides with proper instructions of ‘Dos’ and ‘Don’ts’ for safe and seamless installation using Autodesk Inventor.

Business Needs.

- Provide continuous assistance to service engineers on site for efficient assembly and installation.

- Develop 2D installation drawings using CAD platforms from manufacturing drawings available.

- Provide comprehensive and technical guidelines in drawings for installation engineers.

- Attain optimum installation for retail shop fitting products created at the client location.

Challenges.

- Made-to-measure products means limited floor space available for installation posing challenges to installation engineers.

- Understanding and eliminating unnecessary information from manufacturing drawings to develop installation guides.

- Disassemble the shop fitting product models in Inventor and understanding step by step assembly and conjunctions of various elements.

- Need to align installation/user guidelines with geography specific standards.

HitechDigital’s Solution.

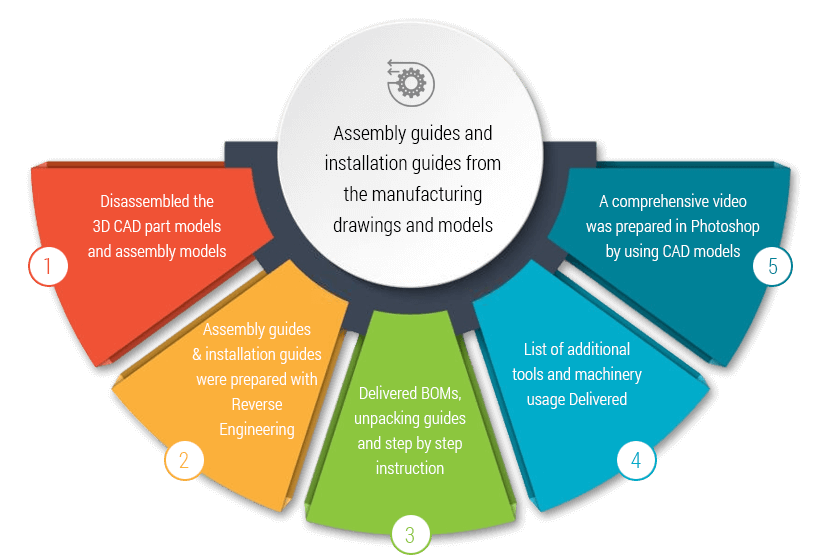

HitechDigital project team delivered assembly guides and installation guides from the manufacturing drawings and models created in Inventor to help service engineers working onsite at client’s end long with a sequencing video in Photoshop. The project team also reverse engineered the available inventory and delivered a novel shop fitting product to be deployed for use at the store location for inspiring shopping worlds.

Approach.

- HitechDigital engineers, step by step, disassembled the 3D CAD part models and assembly models to study how each element connects with every other element and fixtures.

- With the approach of reverse engineering, assembly guides and installation guides were prepared specifying clear dimensions, optimum spacing, clearance etc.

- Project engineers delivered BOMs, unpacking guides and step by step instruction for installation with pictures and list of Dos and Don’ts safety instructions.

- List of additional tools and machinery usage along with recommendations of use was also delivered.

- A comprehensive video was also prepared in Photoshop by using CAD models in form of STEP files for step by step animation assistance with minute details.

Benefit.

- Proper planning installation was carried out by the client with prior planning schedules.

- Well organized scope of work was available of site engineers.

- Common guidelines were established for similar projects in an optimum way.

Client Speaks.

HitechDigital helped us eliminate the roadblocks our services engineers had to deal with every time we went onsite to install the ready manufactured products. We would recommend HitechDigital’s partnership to anyone in the industry for seamless installation.

Result.

- Significant reduction in material waste and damages with ready guidelines.

- Ease in coordinating multiple activities on site.

- Carrying only the needful tools on site.

- Efficient usage of existing inventory for developing new products.