Client Profile.

Bunded container manufacturer, U.K.

Industry: Energy and utilities

Objective.

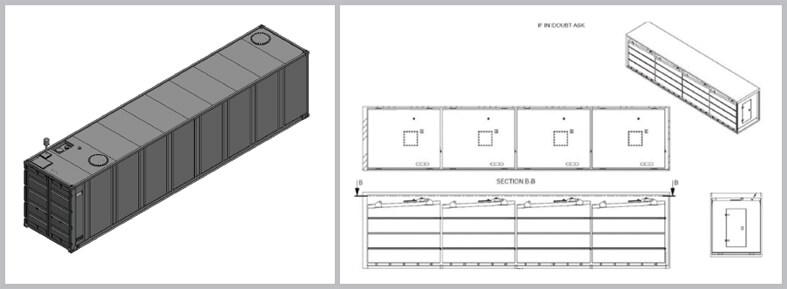

Fuel tank storage designer and manufacturer wanted to convert his designs to CAD models of fuel tanks of varying capacities, adhering to globalstandards. HitechDigital team of engineers and drafters delivered CAD models maintaining regulatory standards such as UN, ADR, PPG2, BS799, UL, etc. along with detailed manufacturing drawings and support at manufacturing sites in China.

Business Needs.

- Design solutions using CAD tools for bunded fuel storage tanks of different storage capacities.

- Prepare CAD drawings with precise calculations of manufacturing requirements.

- Onsite support for maintaining manufacturing quality control.

Challenges.

- Since it was a new product development, it needed a vast and in-depth understanding of product along with its holistic market and globally accepted regulations.

- Reduce design testing costs and time by controlling prototyping iterations.

- Explore opportunities of new 3D CAD and analysis software for analyzing the designs.

- Determining wall thickness to sustain fuel pressure.

HitechDigital’s Solution.

HitechDigital CAD professionals developed storage tank designs considering the regulatory norms of various countries and delivered comprehensive manufacturing drawings to assist manufacturing teams on shop floor. Starting with a design solution for bunded container of 20/40 feet above ground level, HitechDigital currently delivers tanks CAD design solutions ranging from 100 to 16000 Gallons.

Approach.

- HitechDigital engineers prepared 3D CAD models in SolidWorks and AutoCAD from input drawings, and analyzed in ANSYS, for downstream processes.

- Global standard acceptance in UK, Australia, etc. were studied in depth to deliver accurate designs.

- Prototypes were developed and tested in virtual environment to verify the dimensions for safety.

- Fabrication drawings, CAD models, sales drawings and tank shipment layouts were developed and handed over to the client.

Benefit.

- Quick design development cycle due to reduced design iterations.

- Design testing in a sophisticated manner with reduced costs and time.

- Detailed manufacturing drawings assisted in reducing manufacturing time frame.

Client Speaks.

It was really empowering for our design engineers and manufacturing engineers to have HitechDigital on our side from start until the end. Their profound understanding for CAD designing and analysis software was the biggest advantage of entire collaboration.

Result.

- Shortened time to market for new product development.

- Virtual analysis helped in reducing overall costs and saved materials.

- Prototypes are more accurate leading to less rework.

- Ease in customizing products.