The client is US-based bathroom products manufacturer who specializes in bespoke wooden, metal and hybrid vanities for high-end bathroom fittings.

The client’s existing design development process involved repetitive modeling and drafting tasks. And since every order received was custom-made, the CAD engineer had to go back to the initial design model, make design changes, and get approvals from the principal design engineer. It was only after this that the manufacturing was initiated.

The entire approach was manual and hence error-prone and time-consuming. The manufacturer was, thus, looking for a business partner who could provide a solution to streamline and speed-up order processing

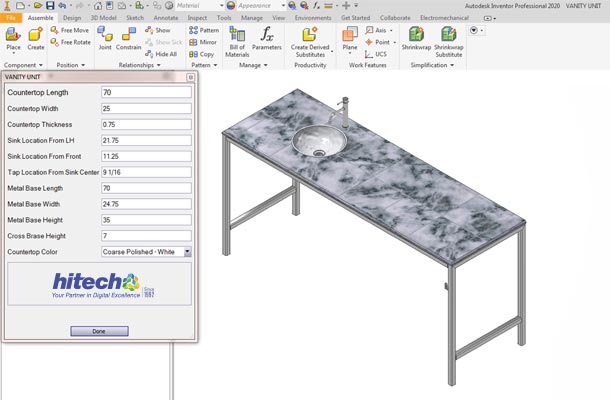

Vanity Unit Configurator

Vanity Unit Configurator

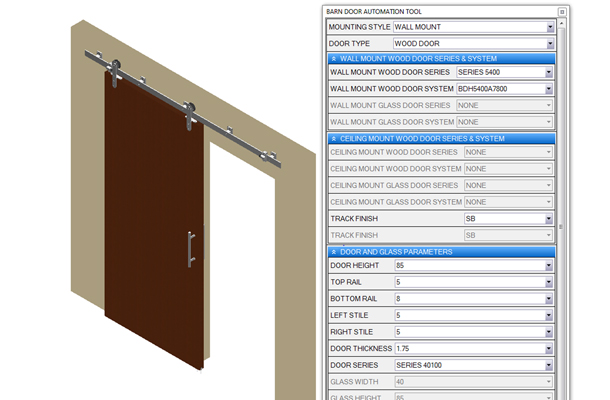

Door Configurator

Door Configurator

An assessment of existing design customization process for vanities showed some major concerns including:

A CAD Configurator using Configurator 360 was deployed to automate internal design request flow and enable faster approvals. It delivered faster design customization and facilitated same day manufacturing even for highly customized vanities.

The client shared existing design models of vanities developed by their engineers as inputs for studying the design intent. Based on the analysis for identifying scope of work, a team of Inventor experts and automation engineers was assembled for configurator development and deployment.