Client Profile.

Design and manufacturer of automatic industrial solutions

Industry: Automotive Industry

Objective.

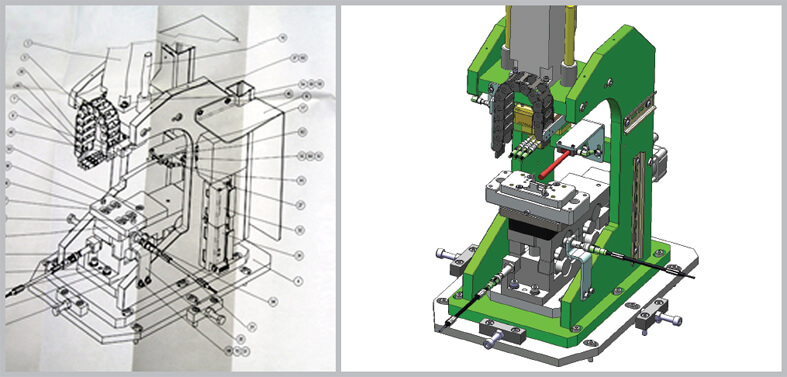

The client who delivers automatic solutions for design and manufacturing the components in automotive sector was facing challenges in altering/updating designs that were frozen on paper drawings. They wanted to digitize the designs in editable format and have access to all the product development stakeholders.

Business Needs.

- Convert the design data to editable CAD formats adhering to international design standard.

- Generate 3D CAD models from paper based drawings for future needs.

- Upgrade the legacy design and preserve it for over time.

- Gain an access to design data all parties involved in product development.

Challenges.

- Interpreting the scanned images and geometrical information throughput.

- Distorted images and missing dimensioning involving extensive interpolation for complete design data set.

- Lacking of design consistency since each drawing is prepared by individual draftsmen on paper.

- Attain control over revisions in designs and document each change carefully.

HitechDigital’s Solution.

- Inputs received in form of scanned images of the paper drawings from the client were duly converted to 3D CAD assembly and part models as well as 2D manufacturing drawings by CAD experts and professionals at HitechDigital.

- Tailor made solutions for the smallest component was delivered using SolidWorks to cater to the client requirement to follow best practices and achieve quality.

Approach.

- Inputs received as scanned images of the paper drawings were cleaned and removed any surplus information.

- Exact dimension were calculated to define geometry in CAD for 3D modeling.

- Extensive interpolation [for missing data or unreadable] for accuracy and tolerances were made.

- RFIs were generated before freezing the models for final production drawings.

- Finalized CAD files were submitted with standard layers, attributes, custom properties and exploded views.

- Three engineers were trained by the client to achieve superior quality in the output who in turn trained 10 more engineers to gauge the quality and pace of conversion.

Benefit.

- Comprehensive information was available to the client for uninterrupted production runs.

- Client to adapt to new technology platform seamlessly.

- Standard libraries of repetitive useful components were generated and maintained for future use.

- Digital documentation was available for future referencing and enhanced communication.

Client Speaks.

The job was done in a very professional manner, with higher accuracy and specialized attention to details we asked for. HitechDigital engineers delivered us exemplary results even for some of the most tedious tasks.

Result.

- 95% accuracy achieved during conversion to CAD.

- Reduced 45% time for new products to market with ease in design interpretation.

- Easy and quick retrieval of design data by any division at the client end.

- Client ventured into new additional partnerships with HitechDigital following the value addition.