A global business, with a 40-year history in manufacturing and installing a range of fabric processing machines to customers in Europe and Asia from its factories at 5 locations in the continents. The company specializes in building personalized products, each one custom engineered to their client’s specific site requirements.

The client was planning to enhance its dipping line for fabrics used in rubber products with a view to resolving issues faced by customers of the existing product – increased operating costs due to high energy consumption and progressive increase in dipping time.

The client required an engineering team to develop concept ideas, propose a complete enhanced product design, and take care of the entire concept to manufacture processes.

Additionally, the client required help in identifying the right suppliers who could manufacture best-fit components of high quality.

Enhancing the product required addressing challenges of loads, speeds and dimensions and materials used, which introduced a significant amount of complexity to the conceptual design process.

The requirement that the new product should improve process control demanded testing and in-depth analysis on multiple parameters to evaluate different mechanical assemblies and measure the price-versus-performance trade-offs.

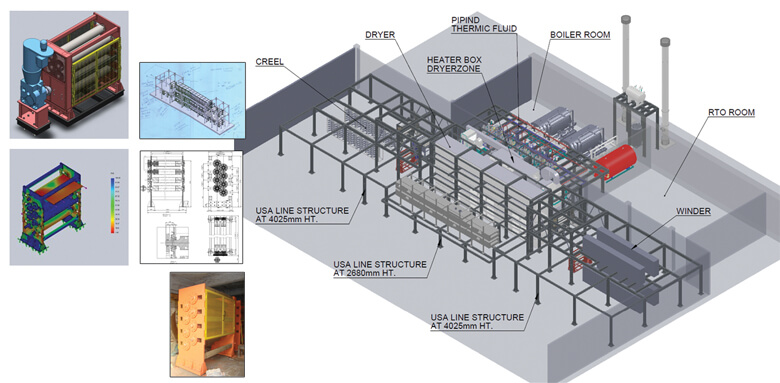

Enhanced existing product design, including component modifications, topology and dimension changes to improve dipping efficiency while reducing part and material costs

This included complete solutions from creating sketches to virtual prototypes to the finalized 3D model of the approved design.

Complete detailed engineering solutions

Delivering the new dipping machine design ready for the shop floor a couple of weeks ahead of schedule.

Helped in identifying and selecting vendors for manufacturing of components

Quality Inspection and Manufacturing Inspection at vendor sites

SOLIDWORKS®, ANSYS WORKBENCH®