Client Profile.

Retail furniture designer and manufacturer, U.K.

Industry: Retail Furniture design and manufacturing

Objective.

Client who is a 30+ year old design and manufacturing company invested in product designing, especially novel retail furniture designs, needed to uplift and suit product lines with customer’s tech savvy touch points. HitechDigital engineers delivered 3D models and 2D manufacturing ready drafts for immediate start of production.

Business Needs.

- Knock-down existing designs and start afresh to meet today’s tech savvy customer base maintaining original design intent.

- Design sustainable and versatile fitting room furniture having continuous usage.

- Modular design and onsite assembly products which are easy in handling during transportation.

Challenges.

- Biggest challenge in knockdown project is to understand the original design intent and accommodate innovations within.

- Designs are made to arrange to a limited floor space and also complement existing furniture in the store.

- Accelerate manufacturing with minimum ECOs in case of knockdown retail furniture designs that are prone to design change orders.

- Generate comprehensive manufacturing drawings in 2D CAD based on original concept sketches to maintain design intent and regional design standards for better user ergonomics.

HitechDigital’s Solution.

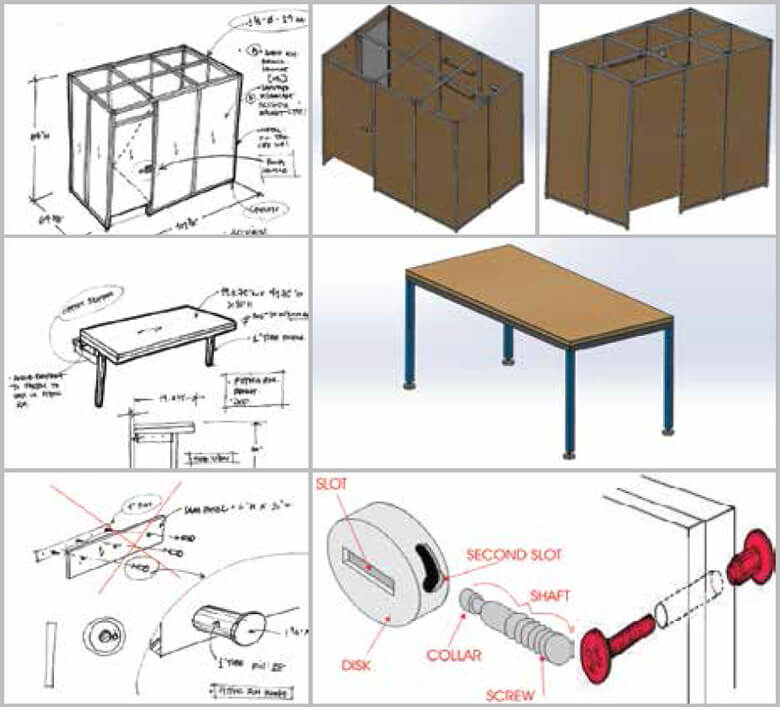

- Drafters and design engineers at the HitechDigital’s end studied the conceptual sketches of the fitting room furniture provided as input, and developed comprehensive 3D CAD models and 2D manufacturing drafts to fabricate the merchandise.

- The project team working as per the client specific requirements for aiding the production teams and delivered modular designs.

Approach.

- Project engineers collaborated with the client to understand their requirements for drawings and materials used such as wood, acrylic or sheet metal for perfect fit and form of fitting room furniture.

- Dedicated project team prepared 3D models and rendered images in SolidWorks for approvals and RFIs.

- 2D manufacturing drawings with BOMs were generated for modular designs and site assembly.

- Prepared assembly drawings with exploded isometric views to facilitate site assembly option at retail fashion stores which can be manufactured remotely.

- HitechDigital engineers helped standardizing the CAD library for client for future use of the models.

Benefit.

- As the designs were developed by offshore resources having better competence, the client could shorten the cycle and utilize their in-house resources more efficiently.

- Modular design approach adopted by the HitechDigital engineers helped the client reduce inventory by one-third.

- Client could reduce the costs by 45% since a knockdown design approach was adopted from the beginning.

- Comprehensive manufacturing drawings were produced which could help client start manufacturing immediately without any significant delays.

Client Speaks.

HitechDigital’s design engineers are very cooperative and have in-depth knowledge of furniture designs that helped us meet our deadlines and deliver the best to our customers. Their assistance impacted our business positively.

Result.

- Shortened design cycle by 70% and cost of designing by 60%.

- Reduced materials waste and efficient manufacturing.

- Deliver customer-centric services.

- Enabled to attract more customers with better finish of the final products.