Client Profile.

Leading player in Construction, Infrastructure, Transportation, Oil & Gas, and Mining

Industry: Oil and Gas

Objective.

TEKLA modelling of each pipe / tray supports for an oil platform with 80,000-barrels-per-day capacity was done while adhering to offshore steel structure standards for welding and holes. Simultaneously TEKLA modelling of stair towers, access platforms, chain guide, and subsea distribution unit was also executed, successfully.

Business Needs.

- Part drawings for pipe / tray supports

- Layout drawings for pipe / tray supports

- All Part drawings with TEKLA model for access platforms

Challenges.

- Maintaining the pace of deliverables with the revision drawings supplied by clients.

- Modelling of each pipe / tray supports as per the coordinates given in the drawings with zero error.

- Maintain all welding and holes standards of client into Tekla model.

- Accuracy and efficiency as a single error could directly affect the fabrication schedule of the client.

HitechDigital’s Solution.

Tekla experts at HitechDigital prepared pipe / tray support layout drawings as per the given standards. Experience of Tekla modelling of pipe / tray supports & incorporating it into the main Tekla structure model helped the client to find location for each pipe / tray supports. TEKLA modelling of stair towers, access platforms, chain guide, and subsea distribution unit came really handy for pacing up the construction process.

Approach.

- Initially client had started with single part drawings for each pipe /tray supports but after 3 months of regular submission and accurate part drawings of pipe / tray supports, client provided us with the main structure Tekla Model.

- We then worked on the Tekla modelling of pipe / tray supports incorporating it into the main Tekla model along with given coordinates.

- With it, we also prepared the pipe /tray support layout drawings, showing position of each and every pipe / tray member, as per the given standards. This layout drawing helped the client to find location for each pipe / tray supports.

- Simultaneously we also worked for the TEKLA modelling of stair towers, access platforms, chain guide, and subsea distribution unit.

Benefit.

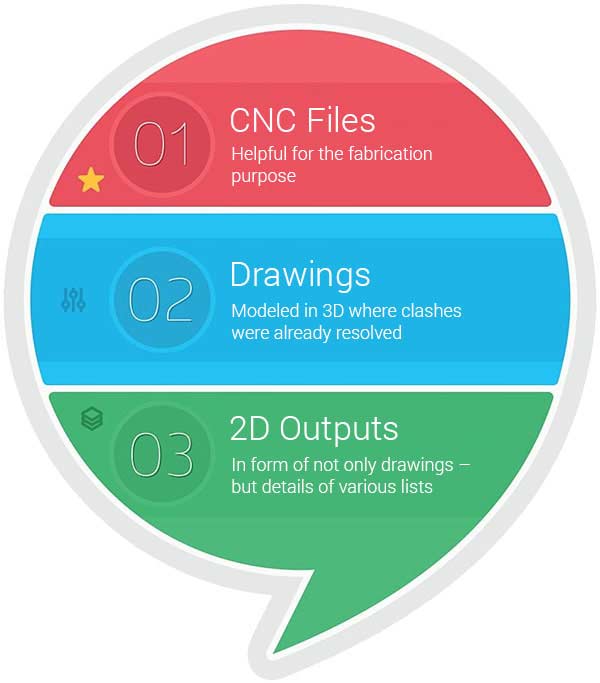

- CNC files provided were helpful for the fabrication purpose.

- Drawings modeled in 3D, where clashes were already resolved.

- Accurate 2D outputs, in form of not only drawings – but details of various lists.

Client Speaks.

HitechDigital has produced detail drawings for more than three of our projects, representing well over 100,000 tons. They demonstrated their commitment to continual improvement, anticipating project specific challenges and addressing those challenges in a timeframe that safeguards the project schedule.

Result.

CNC files provided streamlined the fabrication schedule of the client