- Precast concrete detailing services speed up project execution by accurately communicating field assembly of fabrication components to contractors

- BIM-based pre-cast detailing facilitates project execution by ensuring clash-free and coordinated component fabrication.

- Concrete contractors can optimize resource allocation and scheduling with accurate material tracking and quantity take-offs.

BIM-based concrete detailing services and precast services drive accuracy, flexibility, and overall project efficiency. So, it’s no surprise that concrete contractors today are increasingly adopting BIM tools to extract quantity takeoffs for accurate bids and greater profits.

For precast detailing projects, BIM enhances accuracy of placement drawings for field assembly. In designing, BIM helps to address all clashes prior to delivery of precast concrete for field installation and saves costs, time, and rework.

Legacy construction tools reduce construction accuracy and increase project delays and cost overages. In a traditional low-margin work ecosystem, these challenges further degrade construction results. BIM, provides effective solutions and helps concrete contractors overcome these handicaps.

As per Global Market Insights, the precast concrete market is set to reach $168.17 billion by 2026.

Source: GMinsights

Source: GMinsights

Construction challenges faced by concrete contractors with legacy tools

Although contractors are increasingly adopting BIM services for their precast, prefab, and rebar projects, those still using legacy methods are bogged down by construction challenges.

- Insufficient communication and coordination between teams, disciplines, and stakeholders (concrete contractors, general contractors, and designers) increases rework and field risks

- Outdated paper-based systems leading to delayed alterations/modifications and confusion between field teams and the back office over technical 2D drawings

- Lack of details in outdated plans and data resulting in lower productivity

- Inaccurate scheduling done without accounting for changing weather resulting in project delays

- Incorrect tracking of materials hitting profit margins and throwing schedules out of gear

How are BIM and digital twins used in top construction projects?

- BIM and Digital Twins provide unique yet complementary capabilities.

- BIM focuses on design and construction; Digital Twins enable real-time monitoring and predictive maintenance.

- Integrating BIM and Digital Twins enhances decision-making, asset management, sustainability, and efficiency.

5 ways in which BIM services benefit concrete contractors

Let us explore the top five advantages of BIM for concrete contractors.

1. Improved communication through coordinated BIM models

Coordinated 3D BIM models reduce rework costs by improving communication and collaboration among general contractors, subcontractors, and design teams. Eliminating rework helps concrete contractors earn more revenue.

Coordination and 3D modeling of precast concrete with accurate, detailed, and parametric 3D models help in concrete cast planning. Designs with complete documentation for tilt-up panels, formwork systems, cables, embeds, etc. improve field construction quality. BIM 3D models help back office and field teams drive adaptive alterations and keep stakeholders on the same page.

Interference-free 3D BIM models increase collaboration between multiple stakeholders, thus reducing rework. BIM-enabled concrete detailing services drive seamless onsite installation and reduce risks. Accuracies in shop drawings extracted from 3D models for precast detailing provide higher consistency between design, fabrication, and assembly. Communication on platforms such as BIM 360 facilitates quick turnaround, improved file access, and FTR deliverables.

2. Data-rich 3D models enable quick and real-time alterations

Conversion of 2D drawings and data to a coordinated and clash-free 3D parametric model stored on a single platform reduces the probability of errors and fragmentation of information. Further, cloud-based document management with BIM helps in design updates, precast detailing and formwork workflows.

With BIM, accurate and efficient management of RFIs, submittals, and change orders keeps field teams aware of the latest changes in real time. Storing data in a centralized location reduces data management risks associated with the installation of concrete work.

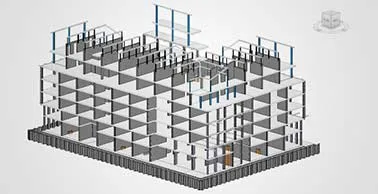

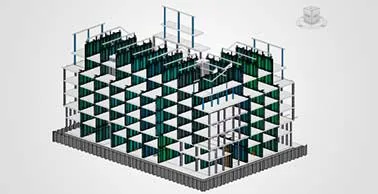

A formwork production company from the Netherlands outsourced its formwork modeling needs to HitechDigital. 2D drawings in PDF format were provided on the BIM360 platform. The team at HitechDigital analyzed the inputs to create 3D formwork models with GA drawings and part counts to showcase the composition and structure of the building.

The client with deliverables at hand could make the production cost-effective and access data on any device. It also helped the client make quick modifications, drive hassle-free documentation, enhance production quality by 100%, and reduce time by 20%.

Structural Model as Input

Structural Model as Input

Structural Model with Formwork

Structural Model with Formwork

3. Clash-free models enhance transparency during preconstruction

In-depth visualization in the preconstruction stage to assess constructability streamlines the actual construction process. Lost time can translate to lower productivity. The absence of documentation, information, and the waiting for solutions from concrete workers or engineers lower productivity. Empowering field personnel with updated plans, information, and 3D models supports quick decision making.

BIM tools allow concrete contractors to document pour cycles, pour locations, foundation data, and sequences backed up by markup plans and site photos. A study in structural detailing in concrete construction suggests that productivity on BIM jobs was 15% higher than in traditional methods.

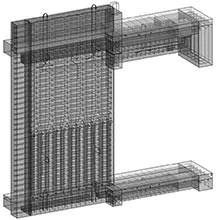

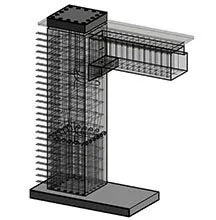

A precast manufacturer/contractor based in UAE and India approached HitechDigital for 3D BIM modeling and Rebar shop drawings. With client inputs, the team created a 5mm coordinated and clash-free 3D BIM model with accurate element fabrication and installation. The 3D BIM model was accompanied by accurate BBS detailing and scheduling, bending and angles with images.

The 3D model carried unique element IDs, accurate quantity estimates, material schedules, and BBS. Enhanced visualization of element manufacturing and installation was achieved through the 3D BIM modeling. With the deliverables at hand, the client could achieve 5mm clash coordination for M60 grade cement. The firm also gained a quick TAT with 100% accuracy, leading to cost and time savings, enhanced production quality, and faster onsite erection.

Column Beam Slab Junction

Column Beam Slab Junction

Column Beam Junction

Column Beam Junction

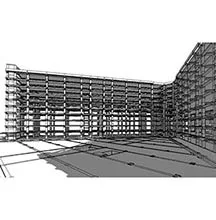

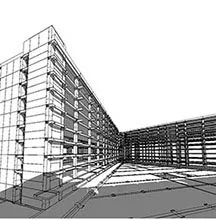

Building External View

Building External View

Building Image

Building Image

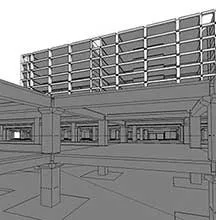

Building Internal View

Building Internal View

Staircase Reinforcement

Staircase Reinforcement

4. Accurate scheduling via interdisciplinary Revit interference check

Planning for unexpected events in the field is critical for concrete contractors. Changes in weather patterns, working conditions, can affect material and equipment forecasting for precast and formwork. It requires 4D simulations with sequencing to visualize planned vs. actual conditions and resolve issues in advance. Creating a schedule floor layout, assigning unique numbers to elements, and extracting a complete sheet setup provide concrete contractors with insights for better decisions.

5. Precise material tracking with accurate and data-packed BOQs

Precast and 3D formwork models supported by concrete outline drawings, safety drawings and accurate concrete estimation with precise reinforced concrete detailing can cut down material waste. Accurate BOQs, BBS, and BOMs enhance the cost estimation process. Material tracking through unique concrete element IDs improves logistics planning to facilitate the quick and seamless installation of precast concrete or formwork elements. Improvements in material tracking and accurate cost estimates reduce potential losses, thus increasing project ROI.

Futuristic view: The road ahead for concrete construction

As technology continues to develop, it keeps providing new solutions for the construction sector to solve old issues. Generative design for precast and formwork detailing through Revit automation, customized libraries, and now 3D printing is becoming routine in housing and infrastructure. Concrete has a significant role to play amid climate changes, exploding populations, and aggressive urbanization.

Concrete contractors are bound to use BIM automation to achieve greater productivity in precast, formwork, and rebar detailing if they are to keep in step with developments. Granular improvements in building materials, material sourcing, design engineering, and a holistic understanding of the built environment are now a must for safer construction. BIM, for concrete contractors, will continue to provide the channel to improve operational efficiencies, design reuse and material waste reduction.

Conclusion

In today’s construction world, BIM provides an essential operational advantage. For concrete contractors, BIM services are a solid lifeline, and a key contributor in protecting profit margins. In a contractor-centric marketplace, owners and general contractors also have to shoulder BIM compliance. That’s the reason it is crucial to adopt BIM practices and tools, and advanced technology, for higher reliability and scalability of operations.

When the stakes are high, as in the construction industry, outsourcing concrete detailing services and precast detailing services to a capable BIM partner can also be a smart move. A majority of concrete contractors have already adopted the practice and are reaping benefits.