- Implementing an MES streamlines manufacturing operations, provides real-time visibility and enables data-driven decisions.

- At the same time, MES implementation also comes with numerous challenges from change management to acquiring the right technology skills where most manufacturers get stuck.

- A proficient MES deployment team ensures smooth transition and builds an effective manufacturing ecosystem.

Manufacturing Execution Systems (MES) play a crucial role in streamlining and optimizing production processes, providing real-time visibility into shop floor operations, and enabling data-driven decision-making.

A study by Markets and Markets suggests that the manufacturing execution system market is projected to grow at a rate of CAGR 9% by 2027. This market growth is attributed to the increased use of automated solutions. But without an MES, using automation across the shop floor becomes a disjointed exercise.

When implementing an MES for any small and medium size of manufacturer, we need to consider multiple industry-specific requirements. These include streamlining production processes, providing real-time visibility into shop floor operations, enabling data-driven decision-making and enhancing shop floor efficiencies.

However, despite all features being present in the software, MES implementation for small manufacturing business can be complex and challenging. Pitfalls and hiccups are common in MES deployment for traditional workflows that include a high amount of human involvement for small and medium sized manufacturing companies.

Table of Contents

The article offers small manufacturers with top five tips to ensure a smooth MES deployment. These pointers will help you unlock the potential of MES and drive real-time visibility, enhanced planning and better production throughput.

However, with any new system implementation, our first task is to assess what can go wrong before or during the process. And that is where we will start.

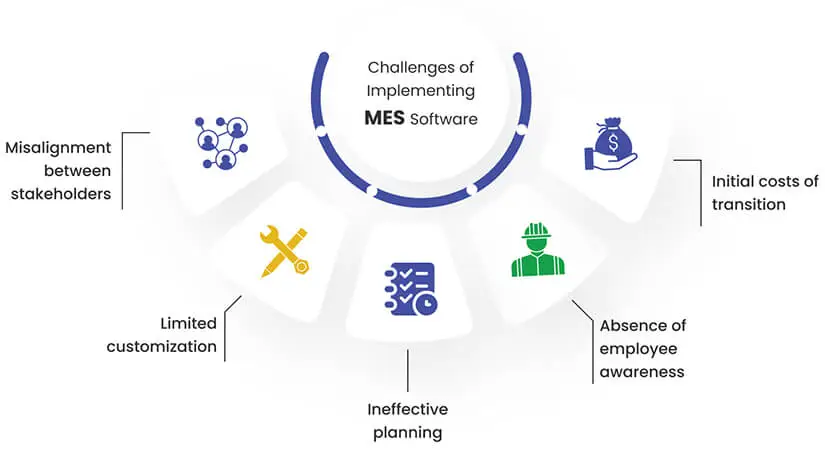

Challenges of implementing MES software for small manufacturing business

Gartner’s studies have found that implementation of MES takes up to fifteen to sixteen months. It is difficult without a clear idea of the challenges involved. For architectural millwork manufacturers, standard off-the-shelf MES solutions can cause implementation issues.

Architectural millwork manufacturers face many challenges when trying to implement an MES and modernize their workflows. These range from high upfront costs and customization requirements to integration with existing software, upgrading existing infrastructure, resistance to change, training and education, and data management. In general, key MES deployment challenges include:

Lack of coherent strategy and alignment among stakeholders

A successful MES implementation requires a well-defined strategy, smooth collaboration and alignment among all stakeholders, including management, IT, and shop floor personnel. Without a clear vision and shared objectives, the deployment process crumbles, leading to delays and suboptimal results.

Limited customization in standard solution packages

By adopting a generic approach, manufacturers overlook the chance to tailor solutions that cater to the distinct nuances, traditions, and values of individual factory locations. Off-the-shelf MES software may not cater to the specific needs of your organization, leading to less-effective implementation.

Ineffective planning, technology, infrastructure, data, and quality issues

Inadequate planning and infrastructure can lead to data inconsistencies, technology incompatibilities, and quality problems. Manufacturers often fail to conduct a comprehensive assessment of their existing infrastructure, technology stack, and data quality before trying for MES.

Absence of employee awareness for MES adoption

Employee buy-in is critical for the success of any MES implementation. Without proper training and awareness, employees may resist the new system, leading to lower adoption rates and reduced effectiveness.

Hard-to-scale systems, and initial costs of change

Implementing an MES can become costly and time-consuming without expert guidance. To ensure a cost-effective and scalable solution it is crucial to select an MES that offers flexible deployment options, such as cloud-based or hybrid models.

Partnering with an experienced MES implementation provider can help minimize risks, reduce costs, and ensure successful deployment. Still, you need to know the basics and the rules of thumb followed in MES implementation, so you know your work is progressing along the right track.

Implementing an MES for job shop owners

- Do you still manually plan production?

- Can you track and trace all manufacturing orders?

- How updated are your reports on machine availability?

- Ask many more questions like this to assess your job shop’s maturity.

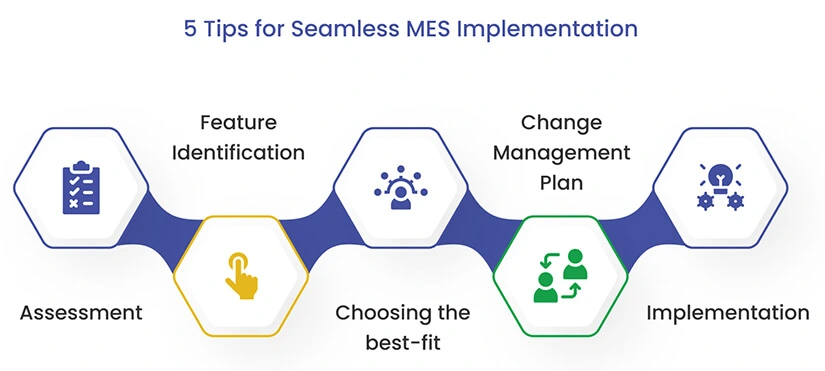

Here are 5 helpful tips for smooth MES implementation

Tip 1: Conduct a comprehensive needs assessment

-

Analyze existing manufacturing processes:

Begin by examining your current manufacturing processes to identify pain points, bottlenecks, and areas for improvement. This process analysis should cover aspects like release of shop drawings, generation of MO, inventory monitoring and dispatch/receipt, machining begins or just machining processes.

By understanding the challenges and inefficiencies in your existing processes, you can better determine the functionalities and features your MES solution should address.

-

Involve all stakeholders:

A common mistake is to conduct needs assessments only with senior team members involved; however, the success of implementation of MES will be defined by understanding the needs of the people at operator level. Ensure that the manufacturing software meets the requirements of all relevant stakeholders like purchase managers, engineers, plant managers, inventory managers and C-Suite executives.

Also engage early with production managers, IT personnel, quality assurance teams, and other stakeholders to gather their input and insights. This collaborative approach helps to create a shared understanding of the MES implementation goals and fosters buy-in from all parties involved.

-

Define objectives and align with business strategy:

Clearly define the objectives of your MES deployment and ensure they align with your overall business strategy. This may include goals such as improving production efficiency, reducing downtime, enhancing product quality, or increasing visibility into manufacturing operations for data-driven decision making.

-

Establish KPIs for success:

Identify the key performance indicators (KPIs) that will be used to measure the success of your MES implementation. These KPIs should be closely tied to your implementation objectives and may include metrics such as production efficiency, equipment utilization, product quality, and on-time delivery rates. By establishing clear KPIs, you can track the progress of your MES implementation and make data-driven decisions to optimize the system’s performance.

Tip 2: Define the key features required in your MES

Identify the specific functionalities

- Production planning and scheduling: Streamlining the planning and scheduling of manufacturing processes to optimize resource utilization and reduce lead times.

- Real-time visibility into operations: Capturing and analyzing real-time data from manufacturing operations to support informed decision-making and continuous improvement.

- Inventory management: Tracking raw materials, work-in-progress, and finished goods to maintain optimal inventory levels and minimize waste.

- Quality control and assurance: Monitoring product quality throughout the manufacturing process to ensure compliance with industry standards and customer requirements.

- Equipment maintenance and monitoring: Tracking the performance and maintenance of production equipment to minimize downtime and maximize efficiency.

- Evaluate Tech Integration Possibilities:

- Seamless integration with ERP, PLM, etc.: Integrating with ERP systems allows for the efficient exchange of data between the MES and other business functions, such as finance, procurement, and sales. Connecting with PLM systems enables the MES to access product design data, ensuring that manufacturing processes are aligned with the latest product specifications. Integration with CRM systems can help to improve customer service by providing real-time visibility into production status and order fulfillment.

- Data migration: Migrating data from legacy systems to the new MES solution is critical for maintaining continuity and ensuring that historical data is accessible for analysis and reporting.

- Legacy applications: Ensuring compatibility with existing applications and processes is essential for minimizing disruptions during the MES implementation.

- Third-party software: Evaluate the need for integration with specialized software, such as advanced analytics tools or industry-specific applications, to enhance the capabilities of your MES software.

- Cloud-based platforms: Consider the benefits of cloud-based MES solutions, which can offer greater scalability, flexibility, and accessibility compared to on-premises systems.

Tip 3: Choose the right MES solution

Scalability: As your organization grows and evolves, your MES solution should be able to scale accordingly. Consider the system’s ability to handle increasing production volumes, accommodate new production lines or facilities, and support additional users. A scalable MES system will enable your organization to adapt to changing business needs and maintain optimal performance.

Flexibility: A flexible MES solution can be easily customized to meet your furniture, cabinet and millwork manufacturing requirements and workflows. Assess the system’s ability to accommodate your specific production processes, like material acquisition, vendor management etc., as there are different teams and multiple processes in the millwork industry. Next is to seamlessly integrate with your existing technology infrastructure and adapt to future changes in your industry or business environment. A flexible MES system will help ensure minimal disruptions to your operations.

Compatibility: Evaluate the MES solution’s ability to integrate with your ERP, PLM, CRM, payable accounts and other critical systems. Also check on its support for data migration from legacy applications. A compatible MES software will enhance transparency, facilitate efficient data exchange, and streamline your organization’s overall technology ecosystem.

Are you looking to revolutionize your manufacturing process?

Discover the difference provided by HitechDigital MES for your manufacturing business.

Questions to ask to make the right decision to choose MES solution

| Domain Specific |

|

| Customization & Configurability |

|

| Scalability |

|

| Quick Setup & Ease of Use |

|

| System Speed & Performance |

|

| Connectors |

|

| Reporting Capabilities |

|

| Drilldown Analysis |

|

| Data Migration from Current System |

|

| System Support, Maintenance, and Upgradation |

|

| Customer Base |

|

| Commercials |

|

User-friendly interface: A user-friendly interface is crucial for ensuring that your employees can effectively use the MES solution. Look for a system that offers intuitive navigation, clear visualizations, and easy-to-understand reporting capabilities. A user-friendly manufacturing system will promote user adoption, reduce training requirements, and enhance overall productivity.

Reporting capabilities:: An effective MES solution should provide robust reporting capabilities that enable your organization to monitor performance, identify trends, and make data-driven decisions. Assess the system’s ability to generate customizable reports, visualize data in real-time, and support advanced analytics. Robust reporting capabilities will empower your organization to optimize its manufacturing processes and drive continuous improvement.

Research and evaluate MES providers:: Finally, research and evaluate different MES providers in the market to find the best fit for your organization. Compare their product offerings, customer support, deployment services, and pricing models. Seek customer testimonials and case studies to gain insights into the provider’s track record and the success of their MES deployments.

Don’t let outdated processes hold you back.

Unlock the full potential of your manufacturing business with our cutting-edge MES solution.

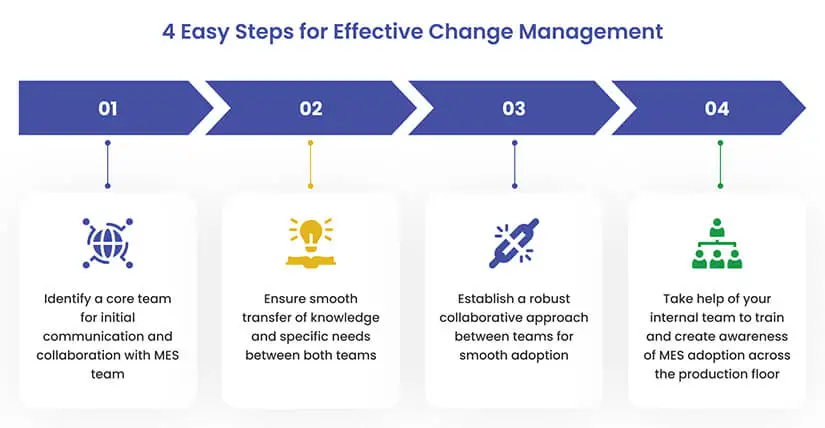

Tip 4: Plan for effective change management

Recognize the impact on employees and organizational culture:

Acknowledge that implementing an MES solution may cause changes in employees’ roles, responsibilities, and daily workflows. These changes can lead to uncertainty and resistance, and you need to proactively address concerns to facilitate a smoother transition.

As per McKinsey report, about 70 percent of change programs fail due to high employee resistance and lack of management support.

Identify core professionals for two-way collaboration:

Select a group of core professionals who are receptive to MES adoption and can serve as champions for the deployment. By involving a certain set of change-makers from within the team in the planning and decision-making process, you can foster a two-way collaboration method. This encourages open communication, feedback, and shared ownership of the MES implementation.

Communicate the benefits and address resistance:

Clearly communicate the benefits of deploying MES to the workforce, highlighting how the new system will support their roles and responsibilities. Open and transparent communication can help to build trust and promote buy-in from the workforce.

Provide comprehensive training and ongoing support:

Ensure that employees receive comprehensive training on the MES solution, tailored to their specific roles and responsibilities. Besides initial training, provide ongoing support through helpdesk services, user guides, and refresher courses.

Establishing collaboration between top and operational level personnel:

Foster collaboration between top-level decision-makers and operational level employees, as both groups play a critical role in the success of the MES implementation. Promote open communication, feedback, and collaborative decision-making among these groups to ensure the manufacturing system aligns with stakeholders’ needs and organizational goals.

Tip 5: Implement in phases and continuously improve

Break down the modular implementation into manageable phases:

Divide the MES implementation process into smaller, more manageable phases or modules to mitigate risks and ensure gradual adoption. This phased approach lets your organization prioritize implementation aspects like data migration, system configuration, or employee training before progressing to the next phase. By tackling the implementation in smaller increments, you can more effectively address challenges, monitor progress, and maintain momentum throughout the project.

Set realistic timelines and milestones:

Establish realistic timelines and milestones for each phase of the MES implementation. This involves considering factors such as the complexity of the project, the availability of resources, and potential challenges that may arise during the implementation. By setting clear deadlines and expectations, you can help your organization stay on track and maintain focus throughout the deployment process.

Establish a system for continuous improvement:

Create a system for continuous improvement and optimization based on feedback and performance analysis. This may involve regularly reviewing KPIs, gathering feedback from users, and conducting periodic system audits to identify areas for improvement. Continuously monitor and adjust your MES solution based on data to keep it aligned with your organization’s evolving needs for optimal results.

Leverage feedback and performance analysis:

Encourage open communication and feedback from employees who use the MES system daily. Their insights can help identify areas for improvement, streamline workflows, and enhance overall system performance. Additionally, analyze the performance data captured by the MES software to identify trends, uncover inefficiencies, and make informed decisions about system optimization.

Facing trouble with MES software implementation?

Let our experts guide you to navigate through the implementation challenges.

How MES solution providers help in seamless installation and implementation

A specialized MES provider or vendor, who can customize and provide an MES solution to your specifications, can help you in the following ways.

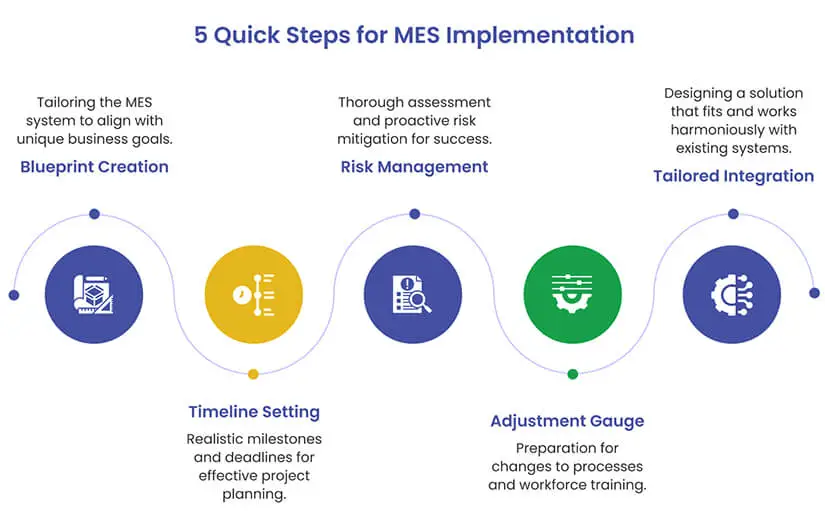

1. Developing the right MES system

A well-defined MES system is the foundation of successful implementation. Vendors work closely with their clients to understand their specific requirements and objectives. This involves identifying key performance indicators (KPIs), defining the scope of the project, and outlining the functionalities. By creating a comprehensive MES blueprint, MES vendors ensure that the system aligns with the client’s business goals and provides a solid foundation for future growth.

2. Providing a realistic timeline

Setting a realistic timeline is essential for managing expectations and ensuring a smooth implementation process. Vendors consider factors such as the complexity of the project, the availability of resources, and potential challenges that may arise during implementation. By establishing a clear timeline with milestones and deadlines, vendors can help their clients plan effectively and maintain momentum throughout the project.

3. Carrying out risk assessment

Identifying and mitigating potential risks is a crucial aspect of MES implementation. Vendors conduct a thorough risk assessment to uncover any potential issues that may impact the project’s success. This includes evaluating factors such as data security, system compatibility, and potential disruptions to the manufacturing process. By addressing these risks proactively, vendors minimize the likelihood of setbacks and ensure smoother implementation.

4. Assessing the level of adjustment required

Implementing an MES system often requires changes to existing processes and workflows. Vendors assess the level of change required and work with their clients to develop a plan for managing these changes. This may involve retraining staff, updating documentation, and changing existing processes to accommodate the new system. By preparing for these adjustments in advance, vendors help their clients transition smoothly to the new MES solution.

5. Designing and integrating the MES solution

Finally, a successful vendor designs a tailored MES solution that meets the client’s unique needs and integrates seamlessly with their existing infrastructure. This involves selecting the appropriate software, configuring the system to align with the client’s requirements, and ensuring that the solution is compatible with existing systems and processes. By focusing on seamless integration, vendors help their clients maximize the benefits of their new MES system and achieve a successful implementation.

To conclude

In sum, what architectural millwork manufacturers should look to when implementing an MES include customization, integration, employee training, data management, and modular MES. Once capital, systems, and experts are secured, the main challenge lies in convincing employees to embrace the change and managing the transition in workflows and habits.

For this, simply providing training is insufficient. Stakeholders need to involve employees in the implementation process, communicate benefits, provide ongoing support, and monitor progress. Providing access to a learning management system and telling employees to learn by themselves is often counterproductive. Where needed, personalized training for employees on the job, and providing ongoing support, help in complete and successful implementation and use of the MES.

Success depends as much on the MES vendor as the MES solution itself.