- Parametric, surface and multibody part modeling in SolidWorks enhance design engineer’s efficiency and creativity during furniture design development.

- Using 3D printing, VR, AR and AI to revolutionize design processes, from rapid prototyping to immersive client presentations and automated design optimizations.

- SolidWorks offers robust drafting tools for the development of precise shop drawings and manufacturing documents to ensure accurate and efficient manufacturing.

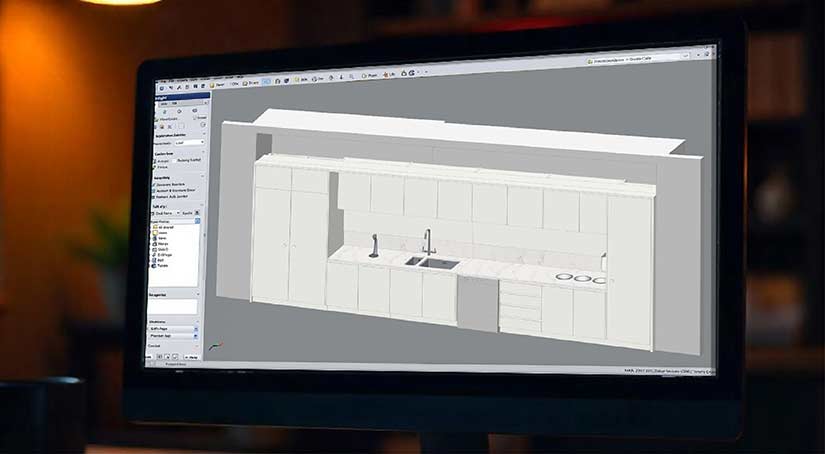

The furniture design industry has changed dramatically with the advent of advanced parametric CAD software. SolidWorks, a leading 3D CAD tool, plays a pivotal role in this transformation. It is used by furniture modeling and drafting services companies because its powerful features can be tailored to bespoke and fixed furniture design. Let’s jump into the advanced 3D modeling techniques in SolidWorks, aiming to enhance efficiency, creativity and precision for furniture design firms and manufacturers.

Table of Contents

- Understanding SolidWorks for Furniture Design

- Key Features of SolidWorks for Furniture Design Drafting and Development

- Top 5 Benefits of Using SolidWorks for Furniture Design

- Advanced 3D Modeling Techniques

- How SolidWorks Drafting Helps Create Furniture Shop Drawings

- 3 Ways to Enhance Furniture Design Efficiency with SolidWorks Tools

- Future Trends in 3D Modeling for Furniture Design

- Conclusion

Understanding SolidWorks for Furniture Design

SolidWorks is a robust CAD tool known for its comprehensive suite of tools that cater to a wide range of industries, including furniture design. Its parametric design capabilities, simulation tools and rendering options make it an invaluable asset for designers aiming to create intricate and functional furniture pieces.

Key Features of SolidWorks for Furniture Design Drafting and Development

- Parametric Design: Allows designers to create models with interdependent features, enabling easy modifications.

- Simulation: Provides tools for stress analysis, motion study, and load testing to ensure the durability and functionality of designs.

- Rendering: High-quality rendering tools such as 3Ds Max and SolidWorks Visualize help create realistic visualizations.

Top 5 Benefits of Using SolidWorks for Furniture Design

SolidWorks streamlines the design process, reduces errors and enhances creativity. Its advanced modeling techniques enable designers to create complex shapes, customize components easily, and visualize the final product with high precision.

- Precision and Accuracy: SolidWorks excels at precise design, capturing intricate curves and material behaviors. This accuracy translates to fewer manufacturing errors and less reliance on prototypes, saving both time and resources.

- Efficient 3D Modeling: The software’s visualization capabilities enable designers to see their creations in realistic 3D renderings, providing a better understanding of aesthetics and functionality before any physical prototypes are built.

- Customization and Flexibility: The parametric design feature facilitates effortless adjustment of design parameters, materials, and finishes, enabling rapid exploration of design variations and customization. This adaptability ensures your designs remain agile and responsive to evolving project needs.

- Seamless Integration with Manufacturing: SolidWorks directly links design and production. It seamlessly works with CNC machines to turn 3D models into instructions for those machines. This minimizes errors during manufacturing, saves time, and boosts overall furniture production efficiency.

- Collaboration and Documentation: SolidWorks helps you easily create detailed drawings, assembly instructions, and BOMs. This streamlines teamwork by helping to keep everyone on the same page, ensuring a smooth project from design to manufacturing.

Advanced 3D Modeling Techniques

1. Parametric Modeling & it’s Application

Parametric modeling involves defining relationships between different elements of a design, allowing for easy adjustments and modifications. In SolidWorks, this technique is particularly useful for creating customizable furniture pieces.

Designers can create adjustable furniture, such as extendable tables or modular shelving units. By setting parameters for dimensions and constraints, modifications can be made swiftly without redesigning the entire model. Some examples include:

- Adjustable Office Desk: By setting parameters for height and width, a single model can accommodate various sizes.

- Modular Shelving: Shelves can be easily added or removed by adjusting parameters and offering flexible design options.

2. Surface Modeling & it’s Application

Surface modeling is used to create complex shapes and organic forms that are difficult to achieve with solid modeling. This technique is essential for designing furniture with unique flowing contours.

Surface modeling is ideal for creating ergonomic chairs, artistic furniture pieces, and components with intricate details. Some techniques of surface modeling include:

- Lofting: Creates smooth transitions between multiple profiles that are useful for designing flowing shapes.

- Sweeping: Generates complex shapes by sweeping a profile along a path, ideal for curved furniture legs or handles.

- Boundary Surfaces: Allows precise control over the shape by defining boundary edges and curves.

3. Multi-Body Part Modeling & it’s Application

Multibody part modeling involves creating multiple solid bodies within a single part file. This technique simplifies the design process and ensures better integration of different components.

This approach is beneficial for designing furniture that comprises several parts, such as cabinets, tables and chairs. Some products that have multi-body product modeling are:

- Cabinet with Drawers: Each drawer and the cabinet frame can be modeled as separate bodies, allowing easy adjustments and replacements.

- Complex Table Design: Legs, tops and supports can be modeled separately and then assembled within the same file.

How SolidWorks Drafting Helps Create Furniture Shop Drawings

SolidWorks drafting capabilities play a crucial role in producing precise and detailed shop drawings essential for furniture manufacturing. Furniture shop drawings are the bridge between the design and production phases, providing the detailed specifications required for the accurate fabrication of furniture pieces.

Here, we explore how SolidWorks facilitates the creation of comprehensive shop drawings for furniture manufacturers, ensuring that every detail from the 3D model is accurately translated into manufacturing instructions.

1. Comprehensive Detailing

SolidWorks excels in providing comprehensive detailing options that are vital for furniture shop drawings. The software allows designers to create detailed 2D drawings from 3D models with ease. This includes the ability to add dimensions, annotations and notes that communicate crucial information to the manufacturing team. Features such as automated dimensioning and customizable drawing templates streamline the drafting process, ensuring consistency and precision across all documentation.

2. Automated Drawing Creation

One of the standout features of SolidWorks is its ability to automate the creation of shop drawings. Designers can generate multiple views (e.g., front, side, top) and section views directly from the 3D model. This automation reduces the risk of human error and saves significant time compared to manual drafting. Additionally, any updates made to the 3D model are automatically reflected in the associated shop drawings, ensuring that they are always up-to-date.

3. Bill of Materials (BOM) Integration

A critical component of shop drawings is the Bill of Materials (BOM), which lists all the parts and materials required for manufacturing. SolidWorks offers robust BOM integration, allowing designers to generate and include a detailed BOM directly within the shop drawings. This integration ensures that all necessary components are accounted for and provides a clear reference for material procurement and assembly.

4. Tolerancing and GD&T

SolidWorks supports Geometric Dimensioning and Tolerancing (GD&T), a system that defines and communicates engineering tolerances. For furniture design, where precision is crucial, GD&T ensures that every component fits as intended. SolidWorks’ GD&T tools help designers specify allowable variations in the dimensions and geometry of parts, ensuring manufacturability and quality control.

5. Collaboration and Communication

Effective collaboration and communication are essential in the furniture design process. SolidWorks’ drafting tools include features that facilitate these aspects, such as the ability to add detailed annotations and comments within the drawings. This enables clear communication of design intent and requirements to the manufacturing team. Additionally, SolidWorks’ compatibility with various file formats ensures that shop drawings can be easily shared and viewed by stakeholders using different software platforms.

Achieve precision in every furniture design

Collaborate with us for accurate and detailed model creation

6. Customization and Templates

SolidWorks offers extensive customization options for shop drawings, allowing designers to create and use templates that adhere to specific standards or preferences. Custom templates can include predefined title blocks, company logos, and standard notes, ensuring a professional and consistent appearance. This level of customization helps maintain brand consistency and ensures that all documentation meets the required standards.

HitechDigital developed a SolidWorks – DriveWorks-powered table configurator for a UK-based custom furniture manufacturer

The solution enabled customers to design and visualize 3D models of tables online, significantly reducing the design modeling time from 3 hours to 10 minutes.

The configurator also automated sales quote generation and enhanced design accuracy by integrating SolidWorks, streamlining the sales and engineering process while maintaining design intent. This led to a 98% reduction in errors in manufacturing drawings.

Read full Case Study »3 Ways to Enhance Furniture Design Efficiency with SolidWorks Tools

1. FeatureWorks

FeatureWorks is an add-on that automates the recognition of features in imported geometry, making it easier to modify and integrate existing designs.

For furniture designers, FeatureWorks can significantly reduce the time required to adjust imported models, such as hardware components or pre-designed parts.

- Imported Hardware: Quickly recognize and modify bolt holes, hinges and other features in imported hardware models.

- Legacy Designs: Update and refine old furniture designs by recognising and modifying features in existing CAD files.

2. Design Library and Toolbox

The Design Library and Toolbox in SolidWorks offer a collection of pre-designed components and hardware, streamlining the design process.

Designers can drag and drop standard parts like screws, bolts, and fittings into their models, ensuring consistency and saving time.

The library can be customized to include bespoke components tailored to specific design requirements, making it ideal for unique furniture pieces.

3. Configurations and Design Tables

Configurations and design tables allow designers to create multiple variations of a design within a single file, facilitating the efficient management of different versions.

This is particularly useful for furniture manufacturers that produce similar pieces with slight variations in size, material or features.

- Dining Table Variations: Create different configurations for table sizes and finishes within one model.

- Office Chairs: Manage variations in height, armrest style, and material without creating separate files for each version.

Future Trends in 3D Modeling for Furniture Design

As the furniture design industry evolves, cutting-edge technologies are fundamentally transforming how designers create and visualize their concepts. Emerging tools and methodologies in 3D printing, Virtual Reality (VR), Augmented Reality (AR), and artificial intelligence (AI) are at the forefront of this revolution.

These advancements are not merely enhancing existing capabilities, but are redefining the standards of efficiency, precision and user experience in design. SolidWorks’ integration with these technologies underscores a significant leap towards more sophisticated and dynamic design processes. This section explores how these trends are setting new benchmarks and shaping the future of furniture design.

3D Printing: SolidWorks’ compatibility with 3D printing technologies enables rapid prototyping and even final product manufacturing. Designers can quickly create and test prototypes, reducing the time and costs associated with traditional manufacturing methods.

Virtual Reality (VR) and Augmented Reality (AR): VR and AR can revolutionize client presentations by allowing clients to interact with virtual models in real time. SolidWorks models can be integrated with VR and AR platforms to provide immersive experiences.

AI and Machine Learning: AI and machine learning can automate design processes, suggest optimizations, and customize designs based on user preferences. These technologies will further streamline the design process, making it faster and more efficient.

Conclusion

Advanced 3D modeling techniques in SolidWorks offer immense benefits for bespoke and fixed furniture design firms. By leveraging parametric modeling, surface modeling, multibody part modeling, and powerful simulation tools, designers can enhance efficiency, creativity and precision.

Integrating advanced rendering and visualization tools further aids in presenting compelling designs to clients. As technology continues to evolve, staying abreast of emerging trends, such as 3D printing, VR, AR and AI, will be crucial for maintaining a competitive edge in the furniture design industry.

Adopting these advanced techniques will not only streamline the design process, but also ensure high-quality, durable, and aesthetically pleasing furniture products.

Maximize your design efficiency

Speed up your furniture designs with our expert SolidWorks modeling