- Native CAD drawings and 3D models for millwork estimation projects offer a very strong foundation to calculate quantity takeoffs and costs.

- However, this traditional process of QTO is tedious, lengthy and error-prone owing to extensive manual calculation of units, parts and variable costs.

- Overcome the errors in legacy methods by integrating CAD with macros and cost estimation software and accurately calculate millwork takeoff from shop drawings.

Millwork is an important aspect of any construction project whether it is a high-end hotel, resort, or restaurant, or utility facilities, museums, and hospitals. Roughly 20% to 30% of a construction project’s costs can be attributed to millwork. And it may include anything ranging from carpentry and woodwork packages with doors & windows, trimming & paneling, stairs & casework, to exterior finish with wooden and/or metal furniture.

If millwork takeoff and estimates are not incorrect, project budgets fail and contractors lose bids. Alternatively, underbids result in losses for the millwork shop. So, it is imperative to have correct cost estimation and right quantity takeoffs from the start, to stay on track with budgets.

In the race to bid lowest, shops cannot afford inaccurate calculations and spoil contracts.

Challenges with manually calculating millwork takeoffs

In a majority of millwork projects, an estimator calculates quantity takeoffs and provides the wood requirements to the general contractor, builders, and millwork manufacturer based on his/her experience and knowledge.

Estimators manually count quantities from 2D drawings and multiply them with relevant prices for estimating millwork quantities needed across the project. Such an approach invites minute human errors that go undetected until they are magnified in later stages.

Inaccuracies of manual tools

Even today, a huge number of millwork estimators use rolling linear scales, colored pencils, highlighters, legal pads, and calculators. The degree of manufacturing precision of these tools influences the accuracy of costs and quantities calculated with them. A small calculation error causes major deviation from actual values. Additionally, the approach itself is labor-intensive.

More guesstimates than estimates

When the number of parts and components are calculated from paper drawings, the estimator needs detailing such as wood type, conversion scale, measurements in linear foot (lf) or linear meter (lm) etc. for accurate calculation. The required diligence level is often impractical against deadlines, and missing details filled in often on ‘experience’ and ‘instinct’. As a result, guesstimates find an easy spot in the final bid, adding to inaccuracies.

Dependent on expertise of estimator

Interpreting 2D drawings with detailed information takes skills and experience to get the values with unique conditions and annotations. It becomes challenging to measure correct value shapes like linear trim, area, number of components and parts etc.

Accommodating and reflecting design change orders

Shop floor change orders or civil irregularities have to be incorporated in the final blueprints and must be reflected in the estimation sheets. When estimates are done manually, any change order can multiply errors and loss of time, as all calculations need to be redone from scratch.

Digitalized QTO and cost estimation from parametric 3D model and CAD drawings help overcome these challenges.

4 ways digitalization helps millwork estimation and quantity takeoff

1. Parametric 3D CAD models and 2D/3D drawings

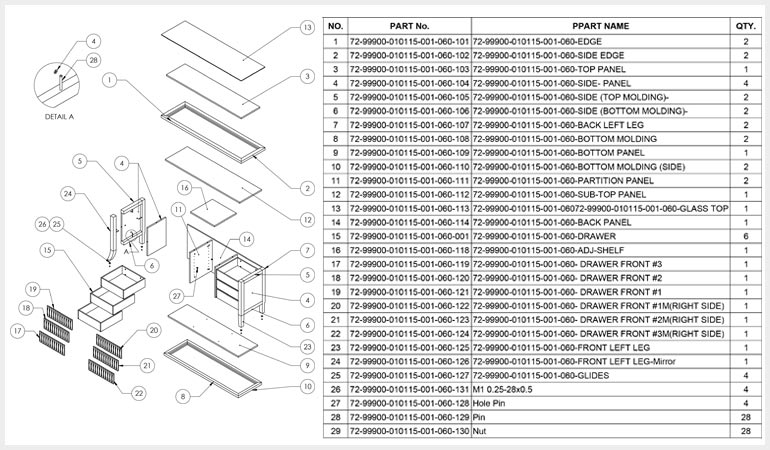

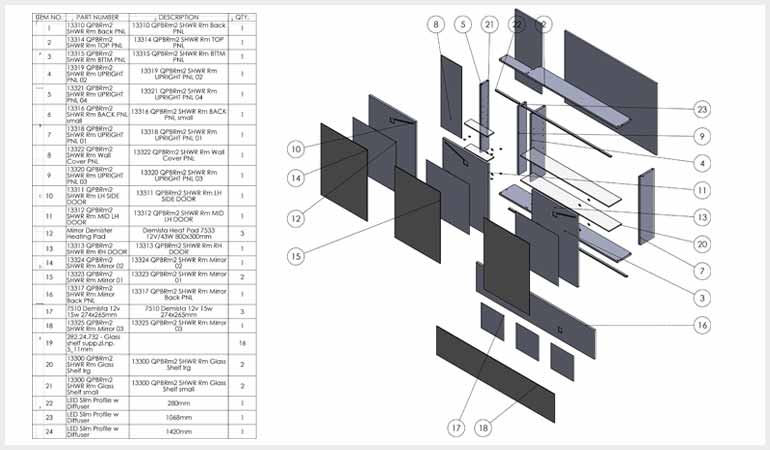

3D CAD tools have an advantage over manual estimation, as they provide accurate model information and capture each minute requirement of millwork part to be used in building project parametrically. Isometric drawings with exploded views, sections and elevations, manufacturing details and installation instructions provide the exact number of parts needed.

The major benefit of using CAD platforms is the ease of making fundamental changes in drawing templates, as it allows reference to any point using spatial coordinates. The designer or the estimator can mark up the changes to keep track and avoid calculation mistakes.

2. Use of libraries to improve productivity

Millwork design engineers can create libraries of reusable and scalable parametric parts for faster designing and accurate estimation. CAD products such as AutoCAD or 2020 Design have in-built blocks, parts, and models for replicating and reusing them during different projects.

When parts are directly used from the in-built libraries, number calculation is automatically fetched and hence is error-free. This feature is particularly useful for repetitively used products such as trimmings, moldings, ceiling and flooring, etc. which can be picked up from libraries and customized as per the need.

Excel-based macros increase the bid-to-win ratio for a cabinet manufacturer.

HitechDigital engineers leveraged 2020 Design to help a leading kitchen cabinet maker for high-end homes in the USA. By using the in-built library for models and drawings of kitchen millwork products in 2020 Design, our millwork specialists developed comprehensive drawings from architectural floor plans to enable digital quantity calculation of accessories, doors, etc.

The furniture manufacturer was able to achieve:

- Increased bid-to-win ratio for cabinet manufacturing contracts.

- Faster and accurate material takeoffs calculation.

- Operational scalability, increased efficiency and opportunities.

3. Metadata information

Estimators and developers can easily export metadata information like weight, material type, finish requirements, volume, length, height, width, radius etc. from digital models or drawings for each unique part. The number of parts, along with quantities, can be calculated and an accurate estimate prepared in required formats within minutes.

Digitalized CAD data allows the estimator to review a 360-degree view of the project, one screen at a time, and eliminate chances of missing details. This way, even a small door or a linear trim is not missed during the count in any large multistorey construction project.

CAD-based digitized workflows help architectural millwork manufacturer save costs

An architectural millwork firm based in Texas, USA, saved hundreds of dollars each month after adopting digital workflows for cost estimation. The firm specializes in high-end wooden products such as trims, wood paneling, cabinetry works, etc. They spent a major chunk of their budgets on printing the drawings, plotting design changes, and extensive labor charges.

By adopting digital workflows they achieved:

- Better cost management for every project.

- Accuracy for each estimate and bid.

- Huge savings on time and costs.

- More contracts with reduced turnaround time.

No resource found with the provided tag.

4. Collaboration and change management

Digital CAD tools, for instance AutoCAD, easily integrate with external 3rd party tools for quantity and cost calculation and unhindered communication across project teams. Manufacturers, contractors and sub-contractors, architects and property owners can use metadata information in 3D CAD models and drawings for updated information exchange.

For example, if digital QTOs created from 3D models are integrated with an organization’s ERP software, detailed insights can be derived for cut lists, material availability, purchases and stocks, planned man-hours, costs etc. Based on these insights, you can better manage your workforce at shop and installation sites.

Bid good bye to tedious and lengthy manual cost estimation processes

Get digitalized takeoffs and cost estimates from millwork CAD models and drawings

Discuss your project →How to maintain accuracy in calculating QTOs

Although digitalization has significantly improved the accuracy of QTOs, errors still slip into the final bids and millwork companies suffer loss of estimated profits.

Here are four ways to approach the complexities of cost estimation:

Sectioning of project

The way to achieve accuracy in estimates is by breaking down the project into smaller sections and then fixing the bid values for each part. One can start calculating quantities floor by floor or even room by room in case of complex projects. An estimator who is proficient in using automation tools can help you create bids more precisely.

Counting the symbols to identify number of components

Identification of logical symbols for instructions in drawings eases QTO count. On the other hand, one should look for standard symbols for recurring remarks like wood type, finish etc. in paneling, trims, door etc.

Checking the scale of drawings

Drawing scale is the most important factor for an estimator to ensure consistency across the drawings verified by the project architect / designer. Wrong interpretation of scales leads you to either over-budgeting or under-budgeting the project cost.

Performing the calculation using buffer values

Buffer values like labor for finished carpentry or casework may not be available as metadata count. Estimators should consider such parameters along with material waste on-site while fixing the final estimate value. Experts define this margin to be between 0.5% and 2% based on project complexity.

Millwork companies are effectively utilizing digital blueprints along with takeoff software to partially automate their processes. The software allows analyzing blueprints and entering the quantity and measurements in prescribed digital formats. In some cases, the software can integrate with an external bidding or quotation program and automate the complete entire quotation process.

Conclusion

A millwork shop’s success begins when the profits are on track with the plans, and is determined by the ability to generate timely and accurate bids. To meet timelines, accuracy is often compromised and bids are either too high or too low resulting in monetary losses.

Digital QTOs and cost calculation methods leverage 3D CAD models and drawings to empower millwork business owners to stay efficient. Digitalization in QTO keeps human errors at bay and enhances collaboration across teams. It establishes businesses as leaders with correctness in estimates with shorter turnaround times and lower expenditure.